Thru-bore strain gage transducer - 1000 µm/m - IP65

- Strain transducer for beam or cylindrical pillar

- Measuring range: +/- 1000 µm/m

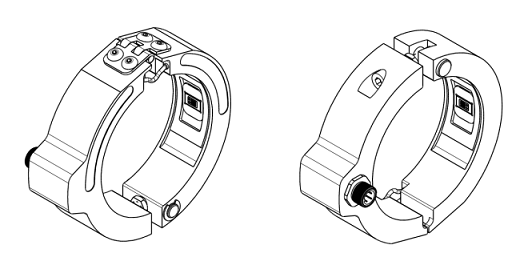

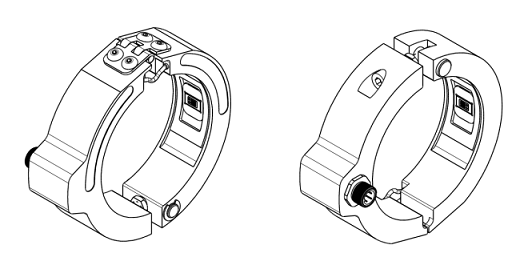

- Consists of 2 half-shells, each with a complete, matched strain gage bridge.

- Gauge bridge installation by pressure + bonding.

- Application comparable to strain gage bonding.

- Construction: IP65 aluminum

- Temperature sensitivity: 0.02

- Dimensions: application specific, inner diam 50 to 220 mm;

- Output signal: 1.3 mV/V

- Output: 5-pin M12 connector + 10 m cable

- Operating temperature: -20 / +85 °C

- Supply voltage: 1-10 VDC (5 VDC recommended)

Presentation

The DAdx strain gage transducer is a reliable, cost-effective solution for high-resolution force and strain measurements on beams, pillars and columns. Technically identical to the direct application of strain gages to the structure, this transducer brings a gain in implementation and stability, with a high-resolution, drift-free signal.

The transducer consists of 2 custom-built half-shells, each integrating a complete strain gage bridge, fully wired and then pressed onto the test body by the combined action of a screw clamping mechanism and glue. Tightness is ensured by a gasket on the contact surface and by the introduction of a resin after installation. For prolonged outdoor use, a silicone seal can be applied.

Measurement range is 1000µm/m. Measurement is characterized by high resolution, very low drift effects and low response time. To meet different types of measurement (stress, torsion, shear, etc.), 3 types of strain gages are available: 10S (FAE4/350 Ohm), 125S or S120P (FAE4/ 1000 Ohm). With the combination of a DAdx strain transducer and a GSV-2 measuring amplifier, strains of 1μm/m (corresponding to 0.2N/mm2) can be repeatedly detected, if zero balancing is carried out periodically.

Mounting and use

The DAdx includes an M6 screw clamping mechanism enabling the sensor to be positioned without additional drilling. Bonding of the gauge to the test body is achieved by bonding the case.

Dimensions

The integration of a DAdx into an application requires a design phase (mechanical engineering department) which takes into account the dimensions of the application, the type of measurement to be carried out, and the level of deformation expected. Achievable diameters range from 50 to 220 mm.

Use

The strain gage is mounted as a full bridge. Conversion from strain to force is done by calibration on the application. Operating temperature range is -20 to +85°C. Supply voltage is 5 VDC.

Applications

- Bridge monitoring

- Silo weighing

- Wind turbine monitoring

- Load measurement on machine tools

- Type

- strain sensor

- Measuring Range

- 1000 µm/m

- Precision (max error)

- 1 %

- Operating temperature range

- -20 à 85 °C

- Analog output signal

- 0-10 VDC

- Résistance du pont

- 350 Ω

- Tension d'alimentation

- 10 Vcc

- Measurement direction

- Traction & Compress.

- Housing

- Aluminium

- Protection Class

- IP65

- Measuring Range (Force)

- ⩽ 1 kN, 1 - 100 kN

- Application

- OEM, low cost

The integration of a DAdx into an application requires a design phase (mechanical engineering department) which takes into account the dimensions of the application, the type of measurement to be carried out, and the level of deformation expected. Achievable diameters range from 50 to 220 mm.

- Connecteur sur câble pour acquisition

- Compensation en température étendue

- Electronique de conditionnement et acquisition

- Sortie connecteur sur demande

- Module TEDS

- Electronique de conditionnement

- Afficheur

- Câblage spécifique