Slip Ring for digital slip rings - Ethernet USB PoE - 12000 rpm

- End of shaft (axial) slip ring

- Designed for digital signals

- Twisted pairs for differential signals

- for Fast or Gigabit Ethernet / USB 2.0 or 3.0 / PoE

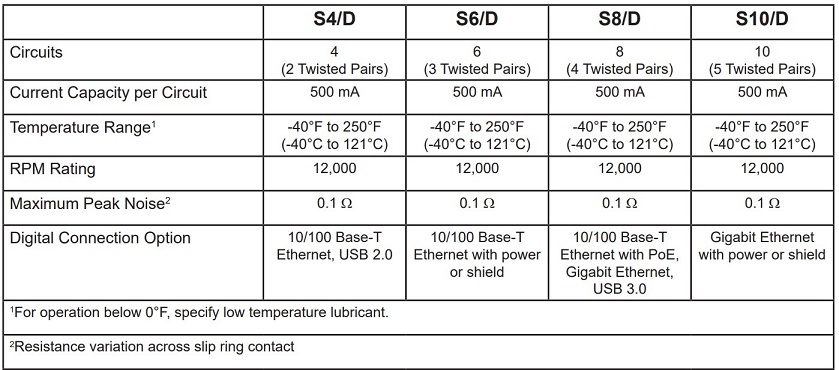

- Circuit number: 4, 6, 8, 10

- Maximum Rotation speed: standard 12 000 RPM - option : up to 20.000 rpm

- Wire termination to color coded solder terminals and/or quick disconnect circular connectors

- Low electrical noise level

- Lifetime: 100 million revolution

- Operating Temperature Range: -40°C to 121°C

- Sealed against dust & permanently lubricated

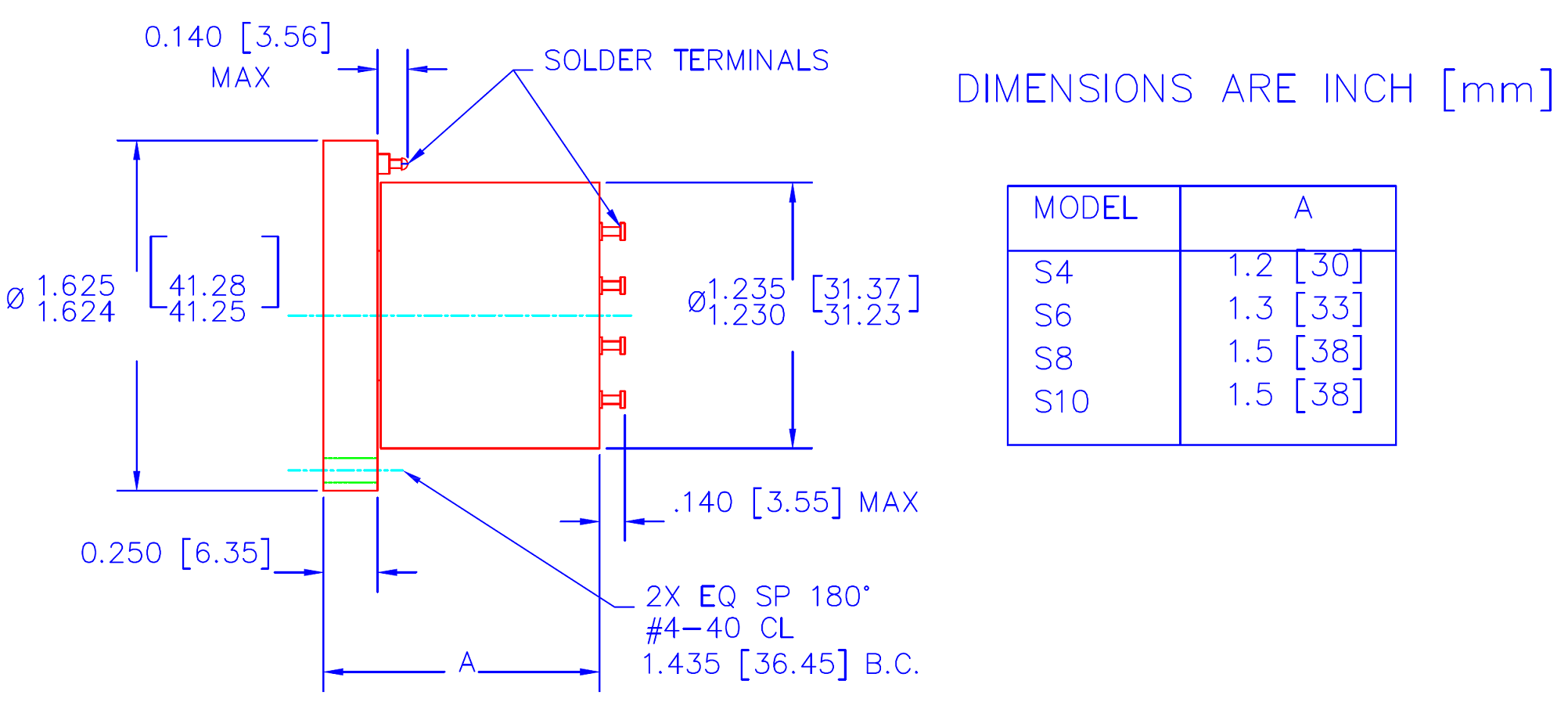

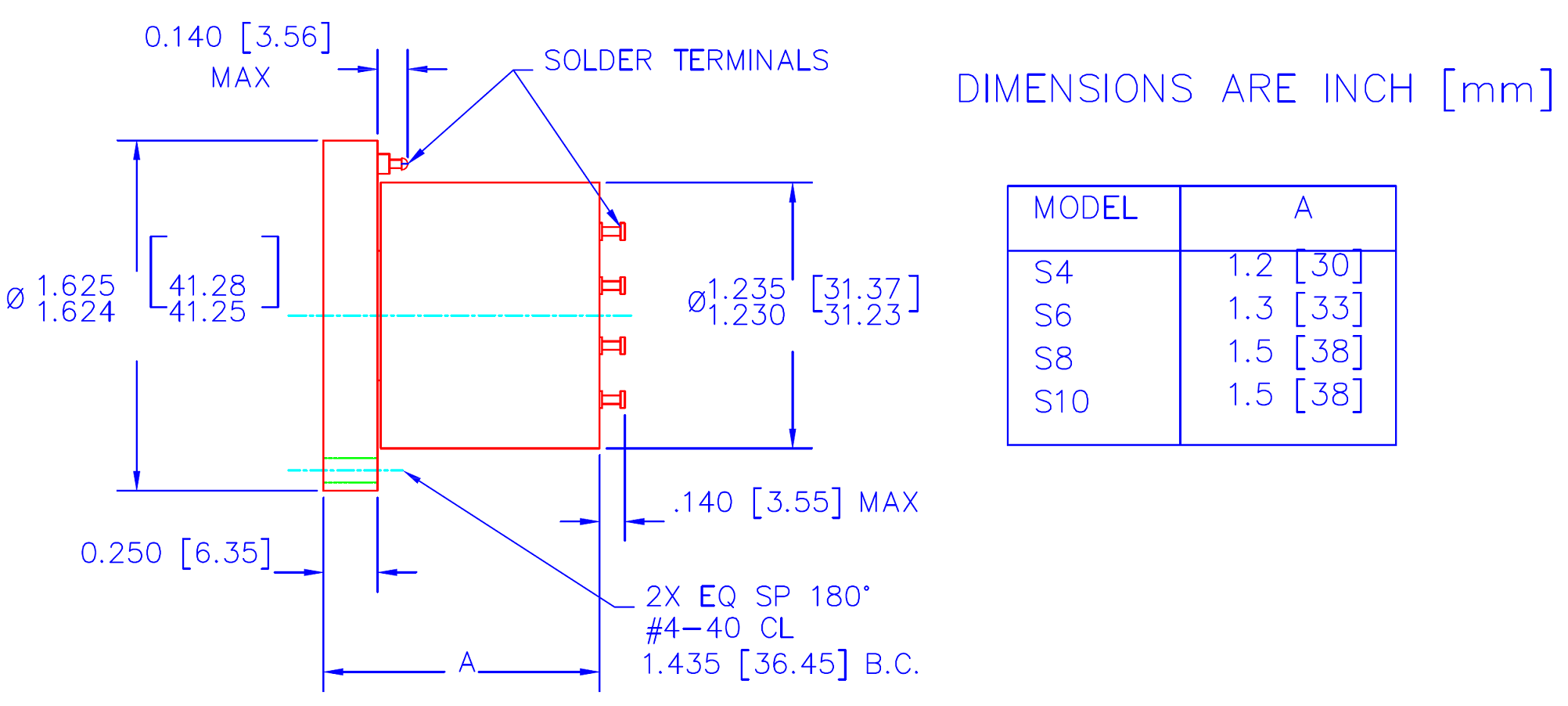

- Rotor diameter: 41.3mm

cost-effective digital slip ring

Michigan Scientific’s S_/D Series Slip Ring Assemblies are based on the proven S-Series, but are built specifically for transmitting digital signals. The S_/D Digital Series Slip Ring Assemblies have special considerations for digital signal protocols, such as twisted pairs for differential signals or routing of the shield through a slip ring connection. They are designed to transfer high speed digital signals and power electrical devices on spinning shafts. Internal components are made of precious metals, which minimize noise and data loss. In addition, a high grade stainless steel case provides protection from dust and other contaminants.

Compared to other slip ring assemblies for digital signals, the these assemblies have longer life ratings and can spin at higher speeds while still maintaining signal integrity. They are available in 4, 6, 8, and 10 connection variations. Connections are made through color-coded solder terminals located on both the slip ring rotor and stator. The lightweight and compact design of these Slip Ring Assemblies make them ideal for use in applications where space is limited.

Installation

The S-Series Slip Ring Assemblies can easily be mounted to the end of a shaft. An adapter may be required for mounting the slip ring to an instrumented shaft. The slip ring rotor is configured with two #4-40 clearance holes, 180° apart, used for mounting. Signal wires from the sensor can be routed along the outside diameter of the shaft or through the center of a hollow shaft. A slot must be machined in the shaft or adapter to open a pathway to the slip ring rotor terminals when signal leads are routed through the center of the shaft.

Available models

Applications

- Torque measurements transmission

- Rear axle measurements

- Vibration measurements

- Acceleration measurements

- Brake measurements

- Gearbox rendering measurements

- Series

- S-Series

- Mounting

- End of shaft

- Circuits

- 4, 6, 8, 10

- Max rotation speed

- 12000 , 20000 rpm

- Wheatherproof

- non available

- Encoder

- no

- Courant maximal par voie

- 500 mA

- Rotor Diameter

- 41.28 mm

- Diamètre stator

- 31.24 mm

- Longueur

- 33 mm

- Température de fonctionnement

- -40 to 121 °C

- Contacts rotor

- Picots à souder

- Contact Stator

- Picots à souder

- Amplifier to connect between the sensor and the slip ring allowing the optimization of the signal's quality

- Weatherproof version for outdoor applications

- Encoder version for information transmission

- Custom stator connector

- Longer lifetime option

- High speed option

- Customized for exterme vibration

-

Custom wiring (cable length, connectors)

-

Signal conditioning for strain gage

-

Signal conditioning for thermocouple

-

Amplifier Housings

-

Connector Brackets

-

Fender Bracket

-

Rotor Adapters

-

Wheel Adapter Plates

-

Wheel Mounting Hardware

Related products

SHORT S-SERIES