Wheatherproof 7 connection tubular slip ring – 1.2" – 3500 rpm

- Tubular slip ring with 7 connections

- Ideal for automotive half shaft torque measurements

- Mounts on shafts up to 1.2” (30 mm) in diameter

- Rugged stainless steel construction

- Permanently lubricated bearings

- Instrumentation quality rings and brushes

- weatherproof

- Operating temperature : -40 to 121°C

- option 60 ppr encoder and/or amplifiers

Overview

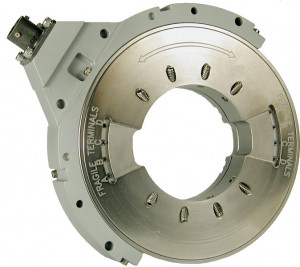

Michigan Scientific’s B7-T-1.2W Weatherproof Slip Ring Assembly is ideal for applications that require a slip ring to be mounted directly on a rotating shaft. The B7-T-1.2W was designed to make long-term, all weather (not submersible), torque measurements on automotive half shafts, but can be used in other applications with a shaft up to 1.2” in diameter (larger bores are available, consult factory).

The slip ring sealing system protects against water spray, grit, dust, mud, slush, and snow.

Connections to strain gages, thermocouples, and other sensors are made via color-coded solder terminals located on the slip ring rotor. Each slip ring assembly includes a 15 ft stator cable with a protective rubber boot for the connector at the slip ring.

Applications

- torque measurement on half shaft

- endurance tests

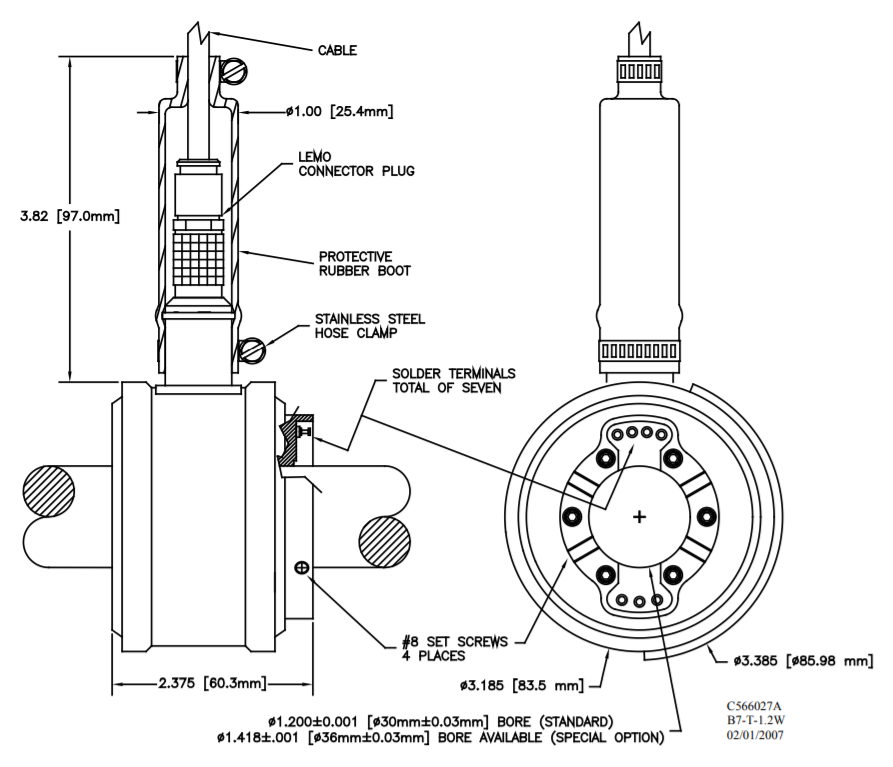

Dimensions

Options

- Stator connection: Soldering terminal or LEMO connector

- 60 ppr Encoder (Model B7-1.2W/E60) : The encoder included in the B7-T-1.2W/E60 Tubular Slip Ring produces a 60 pulse/revolution 5-volt square wave. The TTL compatible signal is produced by a hall-effect sensor, which allows speed to be determined down to 0 mph. The voltage required to drive the encoder can range from 5.5 to 45 DC volts.

- Series

- B-Serie

- Mounting

- Thru the bore

- Circuits

- 7

- Max rotation speed

- 3500 rpm

- Wheatherproof

- included

- Encoder

- no

- Courant maximal par voie

- 1000 mA

- Rotor Diameter

- 30 mm

- Diamètre stator

- 71.8 mm

- Longueur

- 71.7 mm

- Operating temperature range

- -40 à 121 °C

- Contacts rotor

- Picots à souder

- Contact Stator

- Connecteur standard

- Encoder

- Connector type on Stator

- Built-in amplifier

- Custom wiring (cable lengh, connectors)

- Signal conditioning for strain gage

- Signal conditioning for thermocouple

Produits associés

B7-T-1.24W

AMP-SGx-U2

B4-2, B6-2, B8-2