Miniature 6 component force transducer - 200N-1Nm

- 6-component force/torque transducer of the F6D/K6D series

- Force range: Fx, Fy: 50 N, Fz: 200 N;

- Torque range: Mx, My, Mz: 1 Nm;

- Accuracy class: 0.5%;

- Output signal: not amplified

- Dimensions: Ø27 mm x 25 mm;

- Mounting and centering: 6 x M2x0,4 + 2 holes Ø2 mm H7

- Connection: 3 m cable 2 x STC32T-12

- IP65 Aluminum construction

- Weight: 25g

- Calibration certificate and 6x6 interchannel matrix included

Introduction

The 6-component force transducer K6D27 is designed to measure the forces Fx/Fy/Fz and the 3 moments Mx/My/Mz in the three axes. The force measuring ranges are 200 N axial and 50 N radial. The moment capacity is 1 Nm per axis. This "3D force/torque" sensor is extremely compact, with a diameter of only 27 mm.

The sensor is equipped with 24 miniature high-resistance strain gages of the latest generation forming 6 complete bridges. Despite its small size, the 6-component load cell K6D27 is very robust: IP65 housing, temperature-resistant yet flexible Teflon cable, and particularly suitable for applications in medical technology.

The rigidity of the sensor K6D27 in force is about 5000 N / mm, that in moment about 106 Nmm / rad. The overall accuracy is 0.5% (after decoupling), and the sensitivity to transverse forces (crosstalk) is 1%.

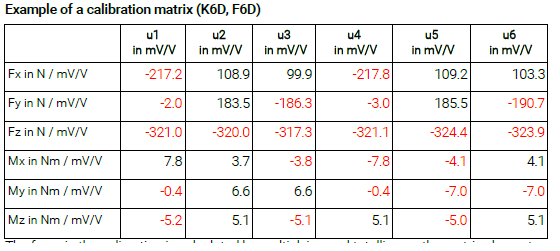

Calibration

The K6D27 sensor is delivered with a factory calibration certificate, as well as a 6x6 coupling matrix, identified in calibration to minimize cross-talks.

The real forces are obtained by multiplying the 6x6 decoupling matrix (M) by the vector I containing the 6 output signals of the K6D27. The origin of the reference frame in which the measured forces are projected is generally the center of the contact surface (see documentation). After neutralization of the inter-channel effects, a force applied on one axis will result in a force variation on only one axis. The accuracy of the measurement is thus improved by a factor of 5 to 10.

Calibration to specific measuring ranges is available as an option, as well as ISO-17025 calibration.

Installation

The two mounting flanges are symmetrical. Each one has two centering contours Ø23mm and Ø17mm as well as a centering pin Ø2mm. The introduction of the forces and the fixing to the bench are carried out by 6 x M2 x 0,4 tappings + 2 Ø2 mm H7 holes (Tightening torques: see here). The application of force is carried out on the surface portions raised by 1 mm.

The sensor is supplied with 5 VDC. The operating temperature range is -10 to 85°C.

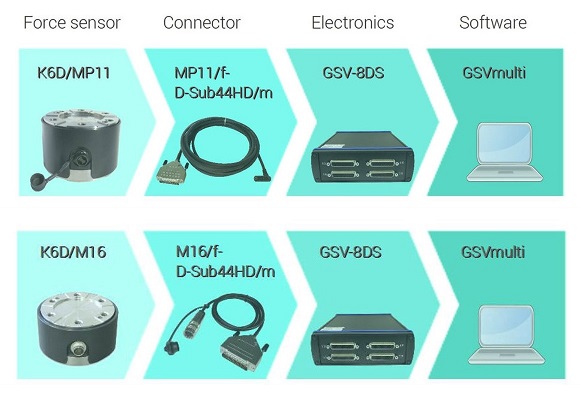

Measuring chain

A complete measurement chain for the supply, visualization and acquisition of measurement signals is configured according to the specific needs of the application.

Connectivity

The sensor is delivered with 2 flexible 12-core AWG32 Teflon cables with a diameter of less than 2 mm. Each connection cable is fixed to one of the two mounting flanges, preventing any measurement error due to the elasticity of the connection cable.

Acquisition module and software

K6D sensors are usually delivered with a GSV-8DS electronics and GSVmulti acquisition software. Main features:

- 8 universal analog channels (gauge, thermocouple, +/- 10V, etc...)

- sampling : 48 kHz

- Real time application of the inter-channel decoupling matrix

- Interface: USB, RS-232, optional: CAN, WiFi, EtherCAT, LAN, LTE, Blutooth...

- Visualization and acquisition software Windows 7, 10

Dll and VI files are also provided for the development of an application under Labview or in C / Visual Studio / C++ / .net

Applications

Application areas for the K6D27 sensor are for example:

- Integration in wind tunnel models,

- Integration into handles and tools in medical technology

- measurements in sports medicine and biomechanics

- Control of assembly and handling processes in micromechanics.

For example, forces of 50 µN and moments of 1 mNm can be measured with the K6D27 + the GSV-8DS and the GSVmulti software.

Options and accessories

- Calibration: Standard or specific, ISO-17025

- Cable and connector for GSV

- Conditioning and acquisition module GSV-8DS, GSV-8AS or GSV-6LTE

- Extended temperature compensation

- TEDS

- Type

- 6 axis sensor

- Moment capacity

- 1 Nm

- Number of Axis

- 6 Axis

- Precision (max error)

- 0.5 %

- Nonlinearity (% FS)

- ± 0.1 %

- Hysteresis

- 0.1 % FS

- Nonrepeatability

- 0.5 % FS

- Operating temperature range

- -10 à 85 °C

- Zero Balance

- 0.1 %PE/°C

- Sensibilité du gain

- 0.05 %/°C

- Output Signal

- 0.4 mV/V

- Tension d'alimentation

- 10 Vcc

- Measurement direction

- Traction & Compress.

- Housing

- Aluminium

- Protection Class

- IP65

- Measuring Range (Force)

- ⩽ 1 kN

- Application

- OEM, Robotics, Miniature

- Calibration: Standard or specific, ISO-17025

- Cable and connector for GSV

- Extended temperature compensation

- TEDS