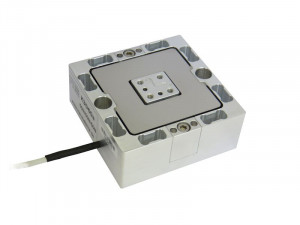

3-axis force transducer 10 to 500 N - 60 x 60 x 23.5 mm - IP65

- 3-component force sensor Fx, Fy, Fz

- Measuring ranges: ± 10 N, ± 20 N, ± 50 N, ± 100 N, ± 200 N, ± 500 N in all 3 axes

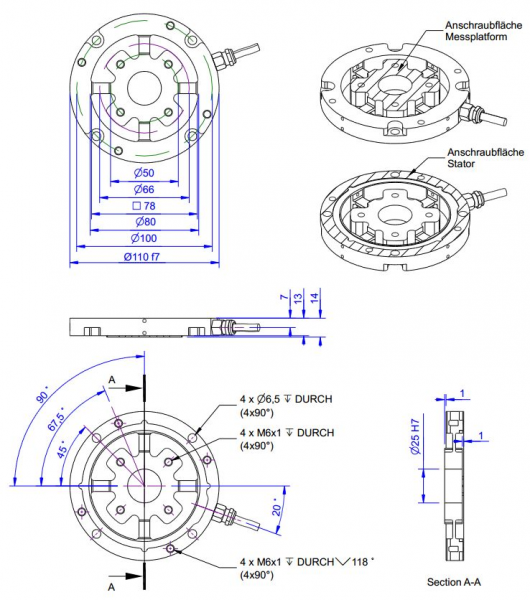

- Dimension: 60 x 60 x 23.5 mm

- Accuracy: < 0.5 % PE (0.1 % optional)

- Construction: aluminium IP65

- Tension and compression measurement

- Output: 3m STC-32T-12 12 wire cable

- Weight: 110g

- Force transmission: 4 x M3x0.5 threads

- Resonance frequency: 3 kHz

Introduction

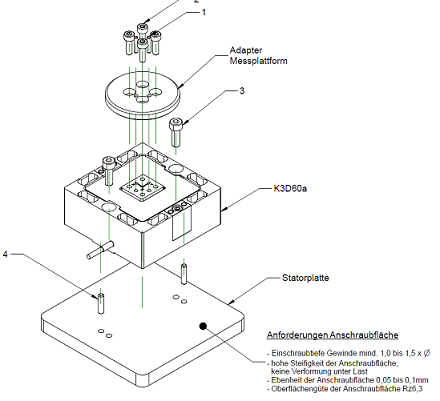

K3D60a 3-component force transducer measures simultaneously the forces Fx, Fy, Fz on three perpendicular directions. The measurement ranges on each axis are between +/-10 N and +/-500 N, the overall accuracy is 0.5% (0.1% optional), and the sensitivity to crosstalk is 1%.

The K3D60a 3-component force transducer is easily installed on machine tools, arms, or test benches. The force introduction and fixation to the stator/bench is done by 4 M3x0.5 threads, as long as the tightening torques requirements are satisfied (see here). A distance of 1 mm must be kept between the adapters and the sensor body.

The sensor is supplied with 5 VDC. The operating temperature range is -20 to 70°C. The output signal is unamplified (0.5 mV/V). The 3 output signals are decoupled by the design of the sensor, and correspond directly to the actual forces. No additional decoupling is required. The sensor is delivered with a 3m cable.

Specifications

The K3D60a sensor is available in 4 measuring ranges:

| Model | K3D60a (+/-10N) | K3D60a (+/-20N) | K3D60a (+/-50N) | K3D60a (+/-100N) | K3D60a (+/-200N) | K3D60a (+/-500N) |

|---|---|---|---|---|---|---|

| Fx, Fy, Fz | 10 | 20 | 50 | 100 | 200 | 500 |

| Maximum applicable moment | 20Nm | 20Nm | 20Nm | 20Nm | 20Nm | 20Nm |

| Electrical Connection | Câble 3 m | Câble 3 m | Câble 3 m | Câble 3 m | Câble 3 m | Câble 3 m |

| Material | Aluminium | Aluminium | Aluminium | Aluminium | Inox | Inox |

Each sensor is delivered with a factory calibration certificate. Calibration to specific measuring ranges is possible (optional), as well as ISO-17025 calibration.

Signal conditionning and acquisition

The acquisition of the raw measurement signals can be done with :

- a PC or PLC acquisition system equipped with a strain gage bridge input card

- or via a strain gage bridge conditioning module with analogue or digital output, connected to a PC or a standard acquisition system.

We recommend the following modules for signal conditioning and acquisition:

- GSV-4USB, 4 input module , USB output

- GSV-1A4, 4 input module, analog output

- GSV-8DS (High performance module, 8 analog inputs)

The visualization and acquisition software included is achieved with the provided software GSV-multi.

Applications

- Robotics

- Production

- Wind tunnel

- Quality control

- Load measurement in medicine, prosthetics, orthopedic engineering or gait analysis

- Measurement in sports medicine

- Comfort / ergonomics measurements

- Type

- beam sensor

- Number of Axis

- 3 Axis

- Precision (max error)

- 0.5 %

- Nonlinearity (% FS)

- ± 0.1 %

- Tension d'alimentation

- 10 Vcc

- Measurement direction

- Traction & Compress.

- Housing

- Aluminium

- Protection Class

- IP65

- Measuring Range (Force)

- ⩽ 1 kN, 1 - 100 kN

- Transducer Series

- K3D

- Application

- Robotics, Miniature

- Connector on cable for acquisition

- Extended temperature compensation

- Electronic conditioning and acquisition

- Connector output on request

- TEDS module

- Conditioning electronics

- Display

- Specific wiring

Produits associés

K3D120 - 3 axes - IP66 - 50 N à 5 kN

K6D68

TR3D-B - 3 axes - miniature - 1,1 à 72 kN