Measuring a force: principle

Force measurement plays a major role in mechanical measurement operations in industrial testing, in research laboratories and in the manufacture of machines for load testing.

The measurement is based on the deformation of an aluminium or steel part, the test body, on which strain gauges are glued. These gauges deliver an electrical signal directly proportional to the micro-deformations resulting from the application of the force.

The design of the sensors requires stress analysis studies of the test body. They allow the optimal positioning of the gauges to be determined, as well as the determination of the required sensitivity/accuracy/measurement range compromise.

The force is expressed (in the SI system) in Newton. Measurements can range from 0.01 N to several MegaN. (10 N = 1.01971621 kg, 10kN = 1019.7 kg and 10 MN = 1019.7 Tons).

Criteria for selecting a load cell or sensor

The first criteria in choosing a transducer are related to the types of tests to be performed, the metrological requirements and the duration of the tests.

The type of tests to be performed will determine the shape of the transducer to be chosen, for example :

-

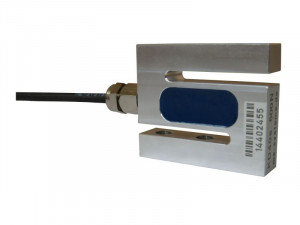

For a sample break machine, occasionally used for compliance testing, an S-shaped load cell may be selected. They have very good accuracy and repeatability, low cost and are often available from stock.

-

For a fatigue test bench** where samples will be loaded to failure, a load cell that combines durability, accuracy and stability should be selected. This type of test generally requires load cells with a high load capacity.

-

Finally, for multi-directional force measurements or if the direction of the force is uncontrolled, a multi-axis load cell is recommended.

-

Other parameters are important such as: temperature sensitivity, metrological data, measurement accuracy, shape of the load cell, price and availability, direction of force.

**We are at your disposal for the selection of your transducers with our extensive experience.

Equipping a test bench with a load cell

The mounting of the load cell on the test bench can be done in several different ways depending on the application. The transducers always have a thread on the lower part, usually the support base, and a thread on the upper part to receive the sample.

For low range load measurements, the transducers are usually mounted on an M4 to M8 thread. Easy to install, the transducers are small and the mounting nuts are reasonably sized. See Products

For intermediate measurement, the centre of the transducer can be tapped from M16 to M42 See Products

Finally, for forces above 900 kN, the threads are between M72 or M120 See Products

Tightening an M120 thread is not necessarily simple (but possible) and requires precautions to avoid applying torques to the sensor that could damage it (see our assembly instructions). See Products

For transducers above 100kN, flange mounting is recommended. The flange consists of 8 to 12 smooth holes (10 to 25 mm diameter) to receive the mounting studs. These very large load cells can be supplied with or without a base.

Industrial force measurement: the PM Instrumentation range

- S-shaped sensors**: for loads from a few Newton to 200 kN](https://www.pm-instrumentation.com/capteurs-de-force-en-s?F7=1)

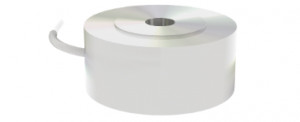

- Wafer sensors: for loads from 1kN to 10000 kN * Beam and washer sensors: for loads in compression measurements

- 6-axis sensors**: Fxyz and Mxyz for laboratory tests](https://www.pm-instrumentation.com/capteurs-de-force-6-composantes?F7=6)

- Button force sensors : Steel compression only sensor

Applications of force measurement

There are many applications in industrial force measurement. Our products are known for their accuracy, stability and durability. Here are some examples of applications:

- Comfort measurements / ergonomic measurements, vibration measurement

- Assembly process monitoring, precision compression transducer

- Primary standard, calibration and metrology laboratories

- Compression on test equipment

- Measurement on hydraulic cylinder system