Wheel Torque Transducer – 5,4 kNm

- Capacity: 5400 N.m

- for small passenger cars and material handling equipment

- Measures driving and braking torque while driving

- Non-linearity: 0.1% of full scale

- Hysteresis: < 0.05% of full scale

- Mounting on 10" and larger wheels

- All weather use

- Temperature compensation from 24 to 121°C

- Signal transmission via rotating collector or telemetry

- Optional temperature and speed measurement

Introduction

The wheel torque tranducer TW9.5 provides a real time measurement of the actual torque at the wheel (My), allowing to measure both transmission and brake torque. Both the torque and combined steer/camber moment load ratings of the TW9.5 transducer are 8125Nm, which fits most of the passenger cars, SUV and light duty vehicles. Highly accurate (non-linearity ≤ 0.1% of FSO, hysteresis < 0,05% of FSO), it has a very low sensitivity to the temperature, thanks to the temperature compensated calibration between 24 and 121°C. Useful on long drive tests, especially when repeated hard brakes increases the temperature, without generating any deviation in the measured data.

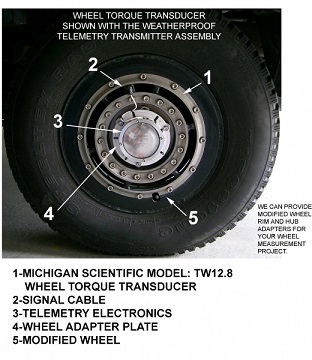

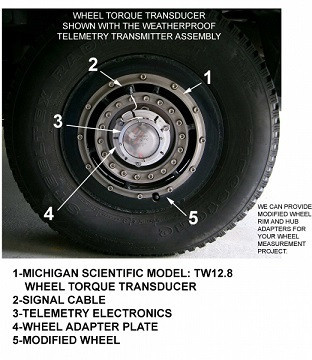

Installation

TW9.5 is designed to attach itself to adapters that simulate production wheel rims. The adapter system is fabricated by generating a profile of the original wheel rim and designing a hub adapter and rim adapter, which fasten to the interior and exterior bolt circle respectively and duplicate the critical dimensions of the original rim. The versatility of this system allows the torque transducer to be used with various wheel rim designs, as long as the rim size is >= 14", and the maximum wheel torque does not exceed 8,1 kNm. High grade stainless steel material and weatherproof sealing combine to provide excellent resistance to corrosion and environmental conditions (rain, snow, ice, mud). The measure is stable over a wide operating temperature range (-40°C à +177°C). In addition, all wires are precisely located to reduce sensitivity to magnetic effects.

Signal acquisition

TW9.5 strain gage bridge powering and the output signal transmission to the data acquisition system can be achieved by wire (slip ring) or wireless (telemetry). The transducer outputs a non-amplified signal (1,5mV/V), an amplifier can be added to the slip ring or telemetry in option. The slip ring version can include wheel speed information, as well as addition measurements (temperature, etc...).

| Slip ring | Telemetry |

|---|---|

|

|

Applications

- Driveline efficiency measurement

- drag torque measurement

- rolling resistance measurement

- braking system assessment

- fuel consumption assessment

Options and accessories

- Slip ring or telemetry

- Signal conditioning (amplifier)

- Higher temperature capability

- Adapters (rim, hub)

- Power supply

- Wheel speed information (encoder)

- Slip ring mounting kit

- Application

- Automotive - LD veh.

- Moment capacity

- 5400 Nm

- High resolution Version

- no

- Rim Size

- 14 - 15 - 16 - 17 - 18 - 19 - 20 - 10 - 11 - 12 - 13 "

- Nonlinearity (% FS)

- ± 0.1 %

- Hysteresis

- 0.05 % FS

- Analog output signal

- non-amplifié

- Tension d'alimentation

- 10 Vcc

- Operating temperature range

- -40 à 177 °C

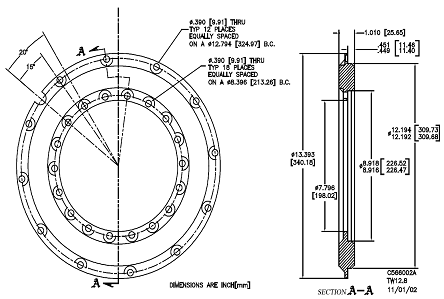

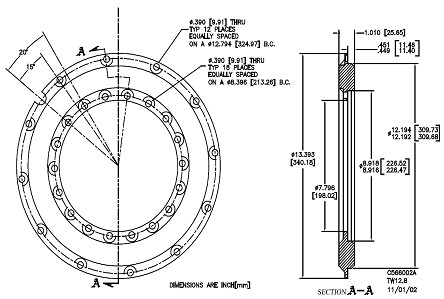

- Outter diameter: 340,18

- Inner diamerter: 198,02

- Width: 25,65

- Rotating manifold or telemetry

- Output signal conditioning

- Extension of the operating temperature range

- Adapter parts

- Strain gage bridge power supply module

- Wheel speed

- Wheel connector fixing kit (rotating manifold)

- Rotating manifold or telemetry

- Output signal conditioning

- Extension of the operating temperature range

- Adapter parts

- Strain gage bridge power supply module

- Wheel speed

- Wheel connector fixing kit (rotating manifold)

Produits associés