Customer need

On-vehicle measurements are a critical part of the design validation process when developing a new vehicle. One important test is measuring torque through drive axles. These torque measurements can be made on half-shaft axles for front-wheel-drive or all-wheel-drive vehicles, or on solid axles on trucks. Michigan Scientific Corporation (MSC) specializes in and manufacturing and for transferring the signal from these spinning parts.

Half-shaft measurements

Torque measurement on a half-shaft requests first the strain gages installation and calibration on a precision torque calibration machine. This can be done by the customer, or by Michigan Scientific using the customer’s production or prototype parts.

The wires from the strain gauges are then routed to a transmission solution from spinning signals. Michigan Scientific offers 2 options for this purpose:

Signal transmission with slip rings

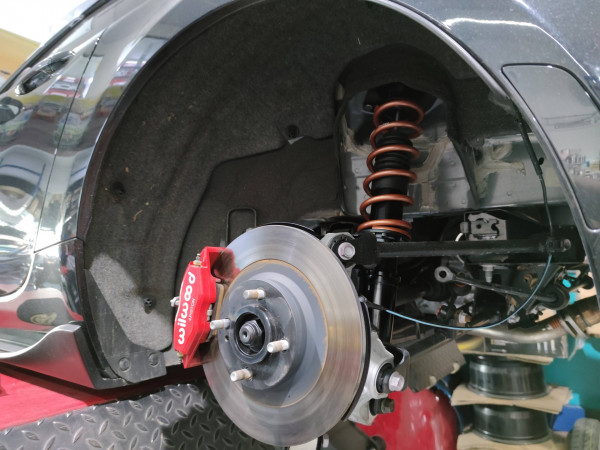

One method of transferring the signal from the spinning axle to the stationary data acquisition (DAQ) system is through the use of a slip ring. MSC designs and manufactures , which are made specifically for half-shafts and use sliding electrical contacts to transfer the signal from the spinning strain gauges.

These Tubular Slip Ring Assemblies are rugged and weatherproof and are designed for off-road use. Optional strain gauge and encoders are available on certain models.

Signal transmission with wireless telemetry

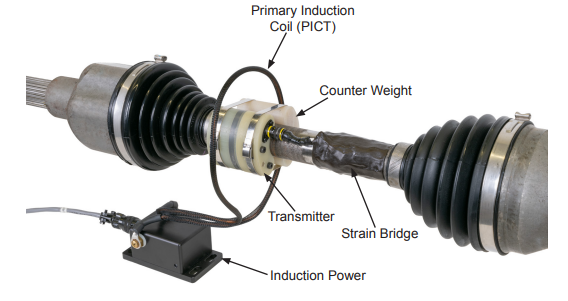

Another method of transferring the signal from the spinning shaft is through the use of wireless telemetry.

MSC Wireless Telemetry Systems convert the strain gauge output into a digital signal and use radio frequency to transmit the signal. They can be installed and removed without disassembling the half-shaft. MSC telemetry can be powered using batteries or an induction power hoop. By utilizing a non-contact induction power hoop, it wirelessly sends power to the spinning telemetry transmitter and allows the shaft to move through the suspension travel without losing power.

Solid axle measurements

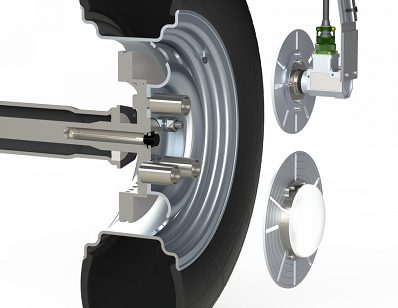

On trucks or other vehicles with solid axles, it is not possible to mount a tubular slip ring assembly or wireless telemetry system because the axle housing restricts the space around the drive axle. However, it is still possible to make torque measurements on this type of axle by measuring torque inside the axle through the use of deep-bore gauging. MSC can instrument the inside of an axle by drilling a hole through the center of the shaft that extends past the hub bearings and applying strain gauges to the walls of the hole. This allows the user to directly measure torque between the differential and hub without any interaction with bearings or seals, all while having a minimal affect on the torsional stiffness of the axle.

In deep-bore gauging applications, signal wires are routed out through the center of the hub and are sealed off with a connector for easy installation.

Then the signal can be routed through a slip ring or a Telemetry Wheel Package, both of which are mounted directly to the standard wheel using wheel mounting hardware. MSC Slip Ring Assemblies have optional encoders for measuring wheel speed and can be mounted to a containing strain gauge and thermocouple amplifiers. Wireless Telemetry Systems are also available for vehicle wheel applications. Telemetry Wheel Packages are weatherproof and are powered with standard 9 V batteries to reduce delays on testing days. Additionally, they are low profile to minimize extension past the vehicle body.

MSC has solutions for many types of axle torque measurements and can design custom instrumentation packages to meet the needs of any new vehicle. To start configuring your axle torque measurement system, please contact us.