Customer Need / Challenge

More than 6,000 bolts are used in the assembly for wind turbines. Regular inspections are both costly and time consuming. The customer wants to monitor the bolts to ensure safety and optimal operation, but with a new quick , less expensive, and easy solution

Solution

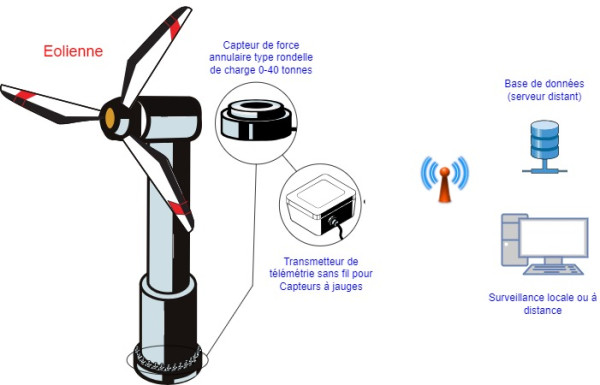

PMi’s solution is to pair multiple Custom Clamping Force Load Cells with the wind turbine’s bolts around the base of the turbine’s pillar. The load cells are installed under each bolt, thus measuring the compression forces. Each LWCF load cell is then connected to a Wireless Strain Bridge Transmitter Module. The load cells will measure the compression forces from the bolts, and the real-time results are transmitted wirelessly from the WTS-AM-1E’s to the provided monitoring Station collecting the data, and sending them every hour to a remote server. The customer can then access the database from his own analysis software or 3rd party analytics tools to visualize the data and detect early failure.

Results

The load cell monitoring system successfully monitors the compression forces of the wind turbine’s bolts in real time. The data collection is completly automated, and the data storage allows the implementation of advanced analysis algorithms for drift detection and predictive maintenance strategies.