Customer

- Designers, operators and managers of power, chemical, hydro and gas turbine plants.

Challenge

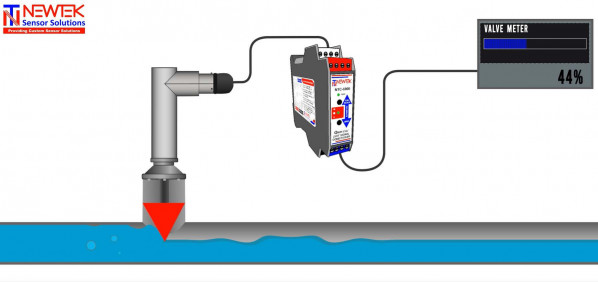

In order to facilitate control and optimise the opening system of gas turbines, the objective is to be able to accurately measure the movement and different positions of the valves or butterflies. A reliable and easy-to-use measuring system is required so that operators can monitor and analyse the movement of the valves as the turbines open and close, without spending extra time and energy. The measuring device should be able to be mounted on the turbine flap and measure the position of the valve stem and its opening.

PMI Solution

The LVDT range of displacement sensors, with measurement ranges available from ± 0.63 mm to ± 250 mm is one of the best solutions. With accurate measurements, LVDT sensors and probes can be used to adjust and control the flow of gases, fuels, liquids or cooling systems delivered by turbines. These sensors can be easily integrated into a control system capable of continuously measuring the position of throttle valves. By selecting a suitable LVDT displacement sensor and linear span, monitoring and control of valve openings can be done continuously.

Customer benefit

- Product reliability: unlimited mechanical life, excellent repeatability, infinite resolution, frictionless measurements, very low contact.

- The choice of a product totally adapted to the customer's application: wide range of sensors with variable measuring ranges, various mountings and outputs, wiring options, robustness (IP 68, extreme temperatures...).

- Ease of use: LVDT displacement transducers can be supplied with electronics (display, conditioner...) delivering a 0-10 Vdc, 4-20Ma output to quickly measure and process the acquired data.