Liquid / Liquid (FDW) or Liquid / Gas (FDD) differential pressure sensor

- Measuring range: 35 mbarD to 70 barD

- Fluid: liquid/liquid or gas/liquid

- Accuracy: 0.25 % (0.1 % optional)

- Output signal: mV, amplified output in option

- Power supply: 10 VDC, or 9 to 28 VDC

- Line pressure: 35 bar

- Operating temperature: -40 to 116 °C if not amplified

- Overload protection: 400 % of the measuring range, maximum 17 bar

- Configurable hydraulic / electrical connection

- Construction: 316 stainless steel

- ATEX version optional

Introduction

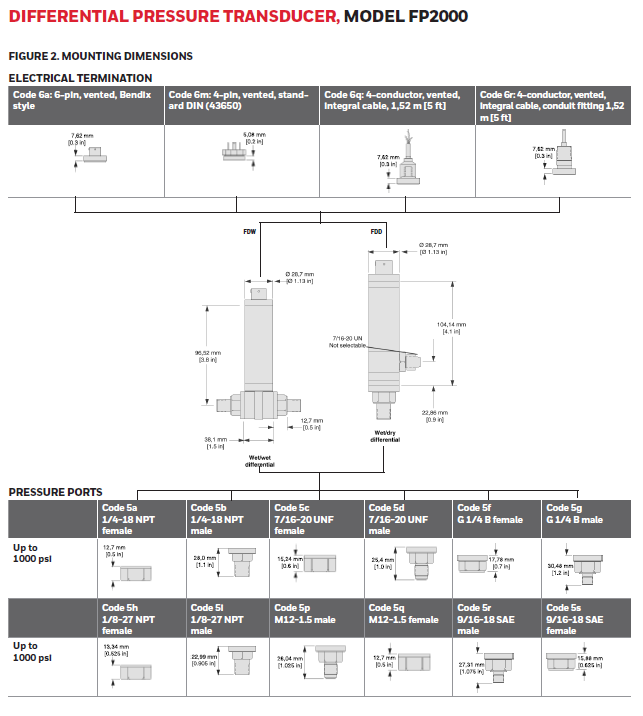

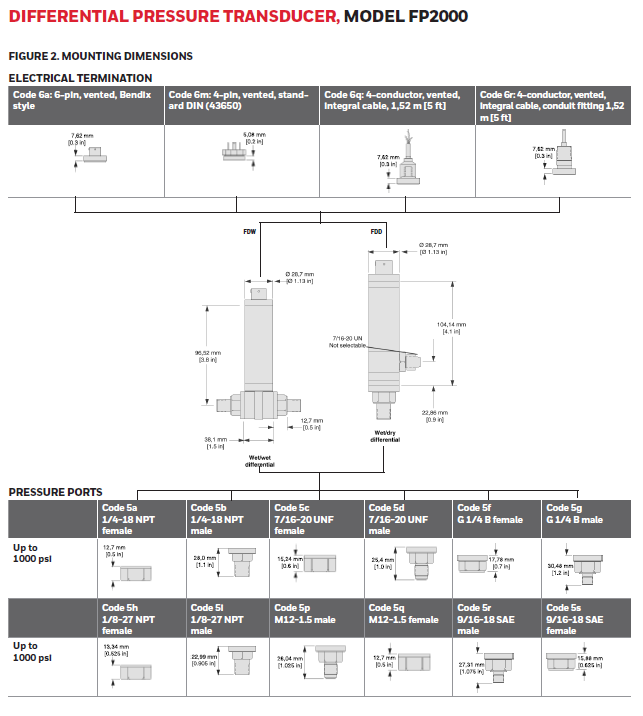

The FP2000 differential pressure transducer is available in liquid-liquid (FDW) or liquid-gas (FDD) configurations. This pressure transducer series is characterized by a wide range of configuration options, as well as by its resistance to high line pressures at very low measuring ranges. The construction is compact and completely welded. The wet parts of the sensors are made of stainless steel 316L or Ha C276, ensuring high resistance to aging and corrosive elements.

The measurement accuracy is 0.25% as standard, 0.1% as an option. The FP2000 differential pressure sensor is available in several ranges from 35mbar to 70 bar. Bidirectional measurement is supported, bandwidth up to 2000 Hz.

Setup

The FP2000 pressure sensor offers a wide range of configuration options

- Type of sensor (liquid/liquid or liquid/gas)

- measurement range

- electrical connection

- hydraulic connections

- integrated or not conditioning

Applications

- Test benches (automotive, aerospace, industry)

- Pneumatic / hydraulic monitoring

- Leak detection

- Pump / compressor control

- Level measurement

- pressure monitoring for preventive maintenance

- flow measurement

- Type

- Differential pressure

- Measuring Range

- < 1 bar, < 100 bar

- Precision (max error)

- ≤ 0.1 %, 0.25 %

- Operating temperature range

- -29 à 85 °C

- Sortie analogique

- analog (mV/V), analog (Voltage)

- Application

- High Accuracy

- Tension d'alimentation

- 10 Vcc

The FP2000 pressure sensor offers a wide range of configuration options

- Type of sensor (liquid/liquid or liquid/gas)

- measurement range

- electrical connection

- hydraulic connection

- Amplified or standard output

- Conditioner

- Display

- Acquisition

Produits associés

Model A-5

FP2000 - FPV