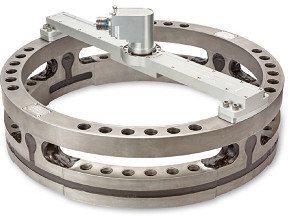

6 Axis Wheel Force Transducer - 150 kN - Class 8 Trucks

- 3 moment and 3 force measurements in real driving conditions

- Force capacities: Fx, Fz: 150 kN, Fy (lateral): 750 kN

- Moment capacity: 40 kNm

- Measures X & Z accelerations

- Signal output : Analog, CAN, CANFD, optional EtherCAT

- Adapts to 19.5 inch and larger wheels

- Environmentally protected

- Temperature compensated

- Rugged stainless steel construction

- Tested to SAE J328 fatigue strength standard

- Swappable slip ring or telemetry system for signal transmission

- ISO-17025 calibration certificate included

- rental option available

Presentation

The LW150 Wheel Force Transducers (WFT) is used to measure forces and moments on class 8 trucks and large off-road vehicles. It provides independent output signals for vertical, lateral, and longitudinal forces as well as camber, steer and torque moments. Being completely weatherproof, it's are ideal for on-road and off-road measurements in all conditions.

Specification

| Maximum Force Capacity, [Fx, Fz] (radial) | 150 kN |

|---|---|

| [Fy] (lateral) at Tire Patch | 75 kN |

| Maximum Torque Capacity [Mx, My, Mz] | 40 KNm |

| Accelerometer range | 55g |

| Sensor | 4 arm strain gage bridges |

| Nonlinearity | ≤ 0,5% of full scale output |

| Hysteresis | < 0,5 % of full scale output |

| Cross Axis Sensitivity after correction | < 1% of full scale output |

| Temperature Range, Operating | -40°C to 177°C |

| Angular Resolution | 0.17° |

| Weight | 20.9 kg |

Installation, Signal processing and data transmission

The transducer LW150 outputs :

- 3 forces

- 3 moments

- 2 accelerations X and Z

- wheel speed and position

Analog, CAN and CANFD output are offered. The raw signals are amplified in the amplifier mounted on the transducer, then sent to the conditionning module CT3 through the slip ring assembly.

| Transducer + amplifier and slip ring | Conditionning module CT2 |

|---|---|

|

|

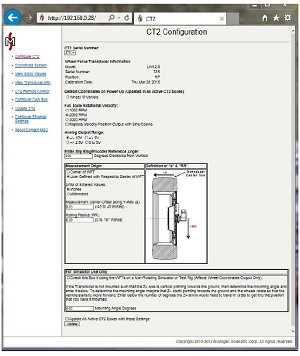

CT3 Transducer Interface Box:

- Performs real-time coordinate transformation and crosstalk compensation

- Easy to use Zero, Shunt Calibration, and Bridge Power Off functions

- Simultaneous Analog, CAN, & Ethernet signal outputs

- Embedded web page enables user to change set-up options, move WFT measurement origin, view transducer static values, create .dbc file

Amplifier and Slip Ring Package:

- Internal X & Z accelerometers

- High resolution encoder for position & speed measurement

- Internal smart chip contains all calibration, zero, & shunt values

- Provides signal conditioning & amplification to the transducer strain gage signals

- Digitizes Transducer, Encoder, & Accelerometer signals

- Supports slip ring

Installation on Vehicle / Spinning application

The matching Amplifier / Slip Ring package easily mounts onto the transducer. It amplifies and digitizes the transducer signals before they pass through the slip ring. The installation on the wheel is completed through a dedicated wheel rim (single or twin) and hub.

| Single rim wheel | Twin rim wheel double |

|---|---|

|

|

Installation on Test Rig / non-spinning application

The wheel force transducer supports installation through flanges or hubs on test rig as well, spinning or not spinning.

Setup

The system configuration and setup is completely done within a simple webbrowser on a PC or laptop connected to the CT3 over LAN. no additional Software is needed.

Applications

- Driving behaviour assessment (comfort, grip)

- braking tests

- pothole testing

- lane change testing

- vehicle dynamics

- durability testing

- 6axis spinning measurements on test rig

- tire testing

- Application

- Heavy-duty - Tractor

- Number of Axis

- 6 Axis

- Force Capacity [Fx, Fz]

- 150000 N

- Force Capacity [Fy]

- 75000 N

- Nonlinearity (% FS)

- ± 0.5 %

- Hysteresis

- 0.5 % FS

- Tension d'alimentation

- 10 Vcc

- Operating temperature range

- -40 à 177 °C

- Special Units for high temperature applications

- Custom designs with alternative output sensitivities / load capacities

- Rim and Hub adapter

- Data acquisition system

Produits associés

LW-2T-30K

LW-2T-40K

LW-2T-50K