Client

Operator of a railway station.

Problem / Challenge

Objective: Guarantee the quality of service, operating safety, limit service interruptions for maintenance. Operating mode:

- Measurement of the loads exerted by the wagons on the rails when entering the station at low speed

- Check that the track is sufficiently dimensioned

- Track diagnostics: detection of track defects (cant, overload, wheel defects, track damage

Another challenge: The solution must fit into a limited budget

PM Instrumentation Solution

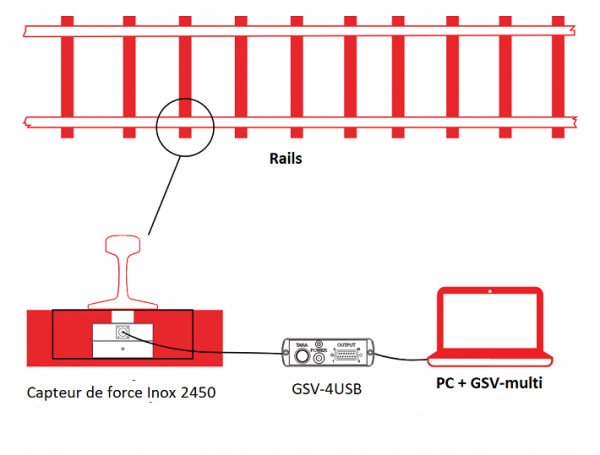

Instrumentation of the tracks using 12 stainless steel 2450 - 50K sensors placed under the rails in direct contact with the rail. The 12 sensors were divided into 3 sets of sensors: 1 at the front, 1 in the middle and 1 at the end of the rail. 3 GSV-4USB modules were used to condition the sensors, and to acquire the measurement signals by connecting them to a recording PC via a USB hub.

Customer benefits

- The technology (strain gauges) and the high rigidity of the 2450 sensor allow the measurement of the average load, as well as the detection of defects on the rails by frequency analysis of the signal.

- The 2450's low temperature sensitivity and IP65 sealing make it suitable for external use with unproblematic temperature variations.

- The GSVmulti acquisition software (supplied with GSV-4USB) allows the acquisition modules to be set up, viewed and the measurement data to be recorded very easily.

- The software is provided free of charge, helping to keep within budget