Ref: GMV2

Torque control monitor in production

- Torque control supervision interface

- compatible with DRT, DRVL, DRB-i, DRBK, DRFS, DRFN torquemeters, etc...

- Programming of test cycles

- Display of instantaneous, peak and average values

- Measurement back-up

- Tool park management (up to 1000 tools)

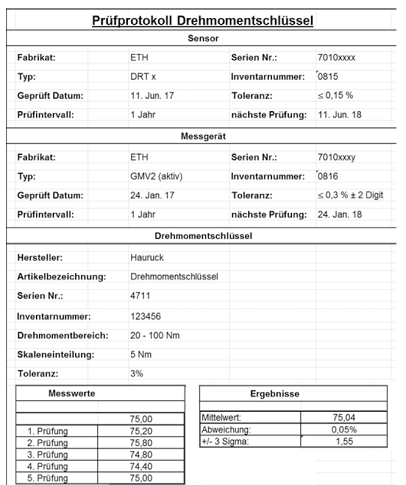

- Automatic generation of ISO 9001-compliant test reports

?

Presentation

GMV2 acquisition system is a visualisation and management solution for various torque measurement applications. The system includes the following functions

- real-time acquisition and recording of measurement signals from the torque meter (internal memory for 1,000 measurements)

- digital display of torque, speed, mechanical power and angle values, and evaluation according to predefined limits (display: continuous, peak values, average)

- Torque sensor power supply.

Operation

- Checking tooling torque

- Power compliance

Applications

- Torque measurement on test bench

- Checking electric screwdrivers

- Torque spanner checks

- Chain end inspection

- Input channels

- 1 , 2

- Input signal type

- Voltage (0-10 VDC)

- Application

- Torque

- Digital output signal

- USB

- Datalogger

- no

- Tension d'alimentation

- 12-29 VDC

- Protection Class

- IP40

- Housing

- Aluminium

Dimensions : 190 x 112 x 51 mm weight : 900g

- Angle signal input

- Interface for PC control

- Tool control interface

- Gauge sensor conditioner

- Analogue output

- Battery for stand-alone operation (autonomy: 8 hours)

- Torque meter

- Connectors

- Switches

- GMV2-PC-Trans software

- USB - RS-232 converter

Produits associés

DRVL - haute précision

Rotary torque meter 0.02 Nm - 20.000 Nm - Accuracy 0.1%

DRFS - torquemeter tools

Industrial rotary torque meter with hexagonal section - 20 Nm - 0.25% accuracy

DRB-I Couplemètre miniature

Static torque sensor ± 0.2 Nm to ±1 Nm - Accuracy 0.3

DRT - Couplemètre statique

Reaction torque for production tooling - ±0-2Nm to ±6kNm - Accuracy 0.25