Reaction torque for production tooling - ±0-2Nm to ±6kNm - Accuracy 0.25

- Strain gauge reaction torque transducer

- Recommended for checking all types of tools, including pulse tools

- 16 measuring ranges available ± 2 Nm to ± 6000 Nm

- Unamplified (1 mV/V) or amplified (+/- 5V) output

- Accuracy: 0.25 % - insensitive to radial loads

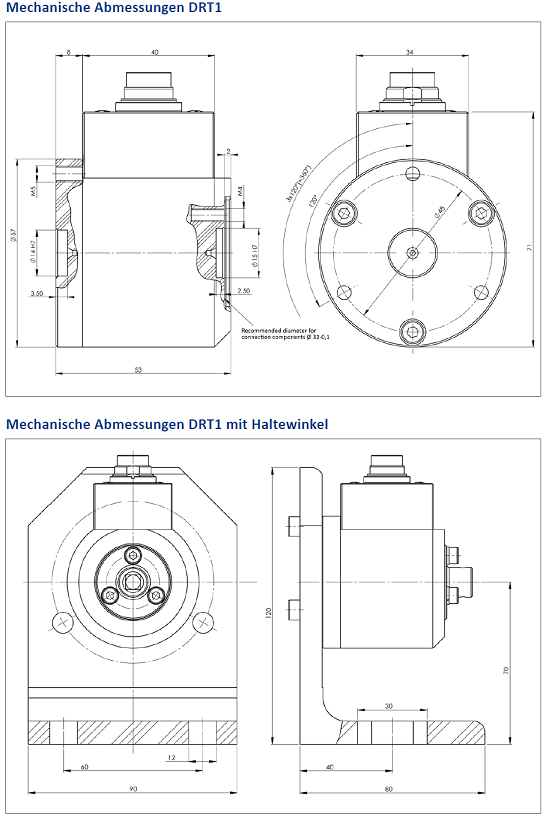

- Fixed installation - optional mounting bracket available

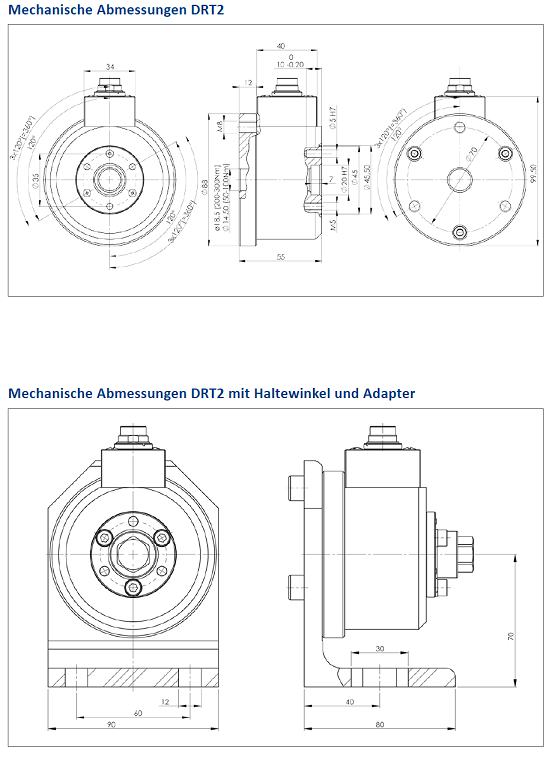

- Optional mounting adapters available (DIN ISO 272, DIN ISO 3121)

- Chip-based tooling management in combination with GMV2 system

- Optional simulators available

- 6 or 12 pin connector output, optional cable

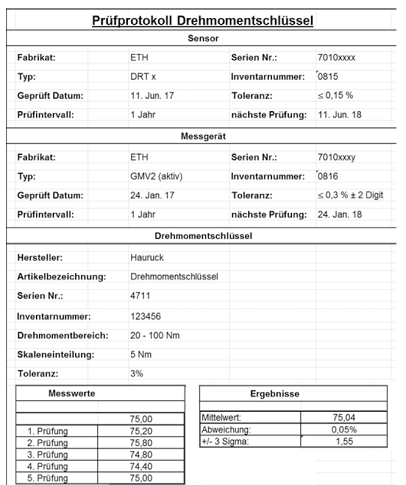

- Supplied with 5-point factory calibration certificate

- Operating temperature: 5 - 140°F

- Power supply: 12VDC

Introduction

The DRT static torque transducer is particularly suitable for static testing of impulse tools, torque spanners, electric screwdrivers, etc. of various types at torque values up to 6kNm, with an accuracy better than 0.25%, excellent linearity (0.1%) and repeatability. The torque transducer's test body is equipped with strain gauges, whose arrangement and the integration of an additional bearing make the measurement insensitive to lateral loads.

The tool to be tested can be attached to the torque transducer in any position using the mounting flange. Various adapters are also available, depending on whether the test is carried out with or without a socket wrench insert.

- Hexagon connector: SW 5.5 till SW13 DIN ISO 272

- 4-sided connector: 1/4" DIN 3121-H

Installation

The DRT torque meter is attached to the wall bracket with two screws. A mounting bracket is available for horizontal mounting. The supply voltage is 12 VDC. The DRT torque meter can be delivered without or with integrated conditioning (+/- 5VDC output).

For large tool parks, the torque verification process can be automated by coupling the DRT with an electronic GMV2 :

- Measurement acquisition

- Definition and implementation of test cables

- Statistical evaluation

- Saving of values (up to 1000 tools), detection of deviations

- Automatic generation of conformity reports

Options and accessories

- Measuring range

- Connection technology

- Conditioner

- Display

- Data acquisition system

- Clamps, adapters, screwing simulators

- Control and evaluation electronics

Applications

The DRT torque meters are designed to check the torque of :

- electric screwdrivers

- pneumatic tools

- torque wrenches, etc.

- rotatif / statique

- static

- Moment capacity

- 2 / 5 / 12 / 20 / 50 / 100 / 200 / 300 / 500 / 1000 / 2000 / 3000 / 4000 / 5000 / 6000 / 10 Nm

- Measuring Range (Torque)

- 1 - 10 Nm, 10 - 100 Nm, 100 - 1000 Nm, 1000 - 5000 Nm, 5000 - 20000 Nm

- Montage_Capteur

- flange

- Nonlinearity (% FS)

- ± 0.1 %

- Hysteresis

- 0.1 % FS

- Signal otuput

- analog (mV/V), ± 5 VDC

- Sortie régime

- Non

- Tension d'alimentation

- 10 Vcc

- Operating temperature range

- 0 à 60 °C

- Connecteur

- Connecteur 6 ou 12 pins

- Protection Class

- IP40

- Poids

- 0.6

DRT1

DRT2

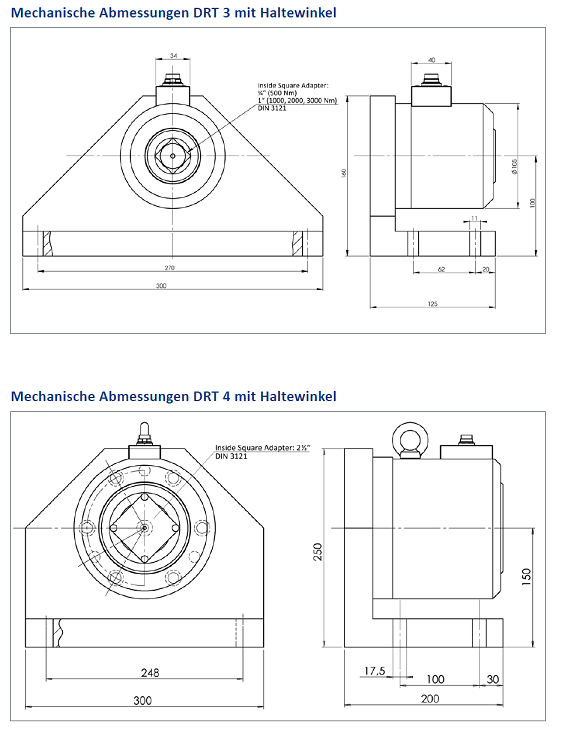

DRT3 et DRT4

- Measuring range

- Connection technology

- Conditioner

- Display

- Data acquisition system

- Woodruff key

- Operating temperature

- Couplings

- Display

- Data acquisition

Produits associés

DRBK - Couplemètre rotatif

MRT - MRTP - MRT2 - MRT2P

DRB-I Couplemètre miniature