3-axis load cell ± 500 kN - IP67 - 400 x 400 x 100 mm

- 3-component force sensor IP67

- Measuring ranges: ± 500kN

- Construction: Stainless steel IP67

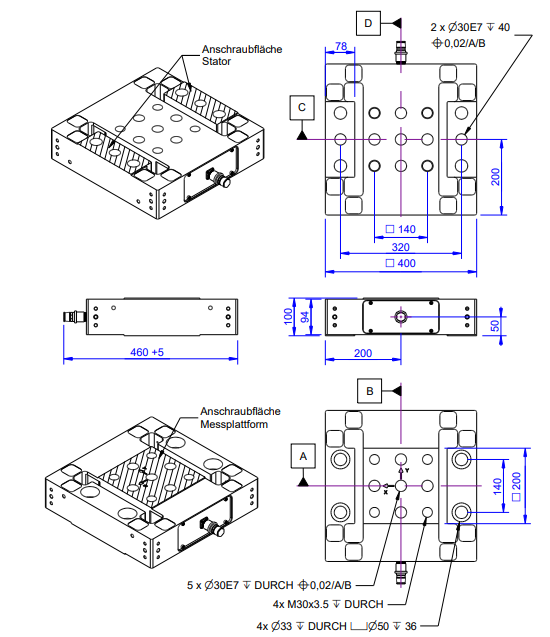

- Dimension: 400mm x 400mm x 100mm

- Accuracy: < 1 % PE

- Output signal: 1 mV/V

- Operating Temperature: -10 to 85°C

- Traction and compression force

- Output: 5 m 12 wires cable

Introduction

The 3-component force sensor K3D400 is the largest 3-axis sensor in the range. It measures simultaneously the forces Fx, Fy, Fz on three perpendicular axes. The measurement ranges on each axis are +/-500 kN, the overall accuracy is 1% and the sensitivity to transverse forces (crosstalk) is 1%. The sensor body is made of stainless steel IP67, and the operating temperature is between -10 and 85°C.

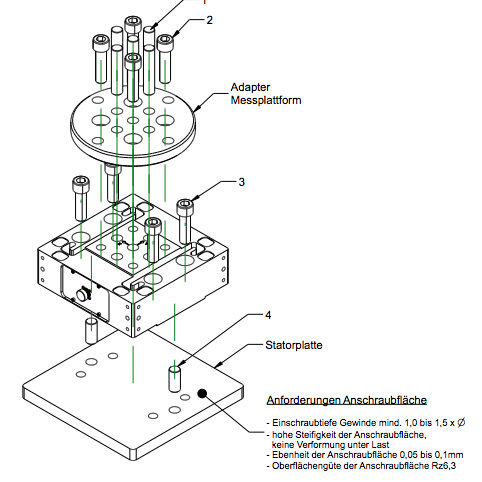

The 3-component load cell K3D400 is easily installed on machine tools, arms, or test benches. The introduction of the forces and the fixation to the stator/bench are carried out by 4 M24 tappings per contact surface, by respecting the tightening torques (see here). A distance of 1 mm must be kept between the adaptation parts and the sensor body.

The sensor is supplied with 5 VDC. The operating temperature range is -10 to 85°C. The output signal is unamplified (1 mV/V). The 3 output signals are decoupled by the design of the sensor, and correspond directly to the actual forces. No additional decoupling is required. The sensor is delivered with a 5m cable.

Specifications

| Model | K3D400 (+/-500 kN) |

|---|---|

| Fx, Fy, Fz [N] | 500 kN |

| Max moment | 15000Nm |

| Connector/Cable | 5 m cable |

| Housing | Stainless Steel IP67 |

Each sensor is delivered with a factory calibration certificate. Calibration to specific measuring ranges is possible (optional), as well as ISO-17025 calibration.

Packaging, Acquisition

The acquisition of the raw measurement signals is done with :

- a PC or PLC acquisition system equipped with a strain gage bridge input card

- or via a conditioning module for strain gage bridge with analog or digital output, then a PC or a standard acquisition system.

PM Instrumentation recommends the GSV series of digital interface conditioning modules for their ease of use and accuracy:

- the GSV-4USB (Conditioner / acquisition module, 4 analog inputs) or its Bluetooth version GSV-4BT M12, which can be equipped with an optional data logger

- the GSV-8DS (High performance module, 8 analog inputs)

- the GSV-6LTE, equipped with a data logger and wireless connectivity

The GSV-1A4 conditioner is equivalent to the GSV-4USB, with 4 analog outputs instead of one serial output.

A visualization and acquisition software is included with these modules (GSV-multi). Dll and VI files are also provided for the development of an application under Labview or in C / Visual Studio / C++ / .net

Applications

The 3-component force transducer K3D400 is designed for robotics, production, material, packaging, food or medical applications such as:

- force measurement in production

- Force control on handling machines

- Force monitoring during assembly

- 3-axis load measurement

- Friction force measurement

Options and accessories

- Calibration: Standard or specific, ISO-17025

- the GSV-4USB (Conditioner / acquisition module, 4 analog inputs) or its Bluetooth version GSV-4BT M12, which can be equipped with an optional data logger

- the GSV-8DS (High performance module, 8 analog inputs)

- the GSV-6LTE, equipped with a data logger and wireless connectivity

- Extended temperature compensation

- TEDS

- Number of Axis

- 3 Axis

- Precision (max error)

- 0.5 %

- Nonlinearity (% FS)

- ± 0.2 %

- Hysteresis

- 0.02 % FS

- Zero Balance

- 0.02 %PE/°C

- Sensibilité du gain

- 0.02 %/°C

- Résistance du pont

- 0 Ω

- Tension d'alimentation

- 10 Vcc

- Measurement direction

- Traction & Compress.

- Housing

- Steel

- Protection Class

- IP67

- Measuring Range (Force)

- > 250 kN

- Transducer Series

- K3D

- Application

- Sbmersible

400 mm x 400 mm x 100 mm;

- Calibration option

- Optimization of the sensor accuracy

- Increase of the accuracy class.

- Conditioners

- Cables and connectors

Produits associés

K3D160 - 3 axes - IP67 - 2 kN à 50 kN

K3D300 - 3 axes - IP67 - 50 à 200 kN

GSV-4USB