Principle of Eddy Current Testing

The Eddy Current testing method is widely used in industry, especially in aeronautics, steel, automotive, railway and nuclear industries. This method consists of creating induced currents in electrically conductive materials (e.g. steel, aluminium, etc.) by means of a sensor or probe. The induced currents flow locally in the material, and their intensity depends on the excitation field, the geometry of the part, and the properties of the material.

Advantages and prerequisites of eddy current testing

The main advantages are : The test is non-destructive, without direct contact with the part * Detection is possible up to 60 mm *The test can be performed on the part Detection is possible up to 60 mm

- The part requires no preparation : works in the presence of oil, dust, etc...

- Excellent resolution, excellent repeatability, wide bandwidth

- High inspection speed (response time < 1 ms)

- Easy to integrate into an automated testing process

- Testing can be done on magnetic or non-magnetic targets

- Can be used in extreme environments (temperature, pressure, etc.)

The requirements for the implementation:

- Good command of the magnetic environment

- A set of parts is necessary to learn the system

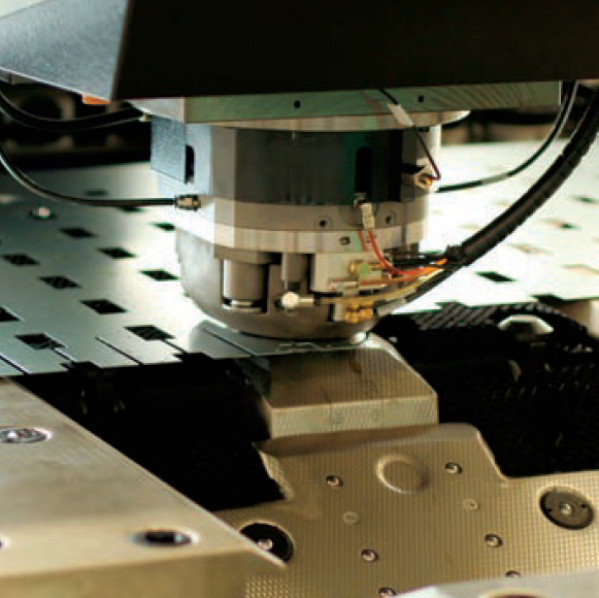

Examples of eddy current testing

- Tapping control

- Measurement of impregnation, coating, paint thickness etc...

- Detection of out-of-roundness

- Thickness measurement

- Crack detection

- Checking the surface condition

- Rotational speed measurement

Eddy Current Control Systems from PM Instrumentation

| Product | Application |

|---|---|

Threadchecker  |

Tapping Control |

SC-2440  |

Thickness measurement, distance measurement, fault detection up to 4mm. Low cost - OEM projects |

KD-2446](https://www.pm-instrumentation.com/kd-2446-sonde-de-proximite-a-courant-de-foucault-05-a-25-mm-10-khz-sortie-analogique-tor)  |

Thickness measurement, distance measurement, crack detection. Cost effective. Numerous probes available. Remote electronics for DIN-rail mounting. Analogue voltage output and digital output. |

KD-2306](https://www.pm-instrumentation.com/kd-2306-capteur-de-deplacement-a-courant-de-foucault-1-voie-1-a-60-mm-50-khz-sortie-analogique)  |

Thickness measurement, distance measurement, crack detection. Bandwidth: 50 kHz. Numerous probes available. Remote electronics for DIN-rail mounting. Analogue voltage output. |