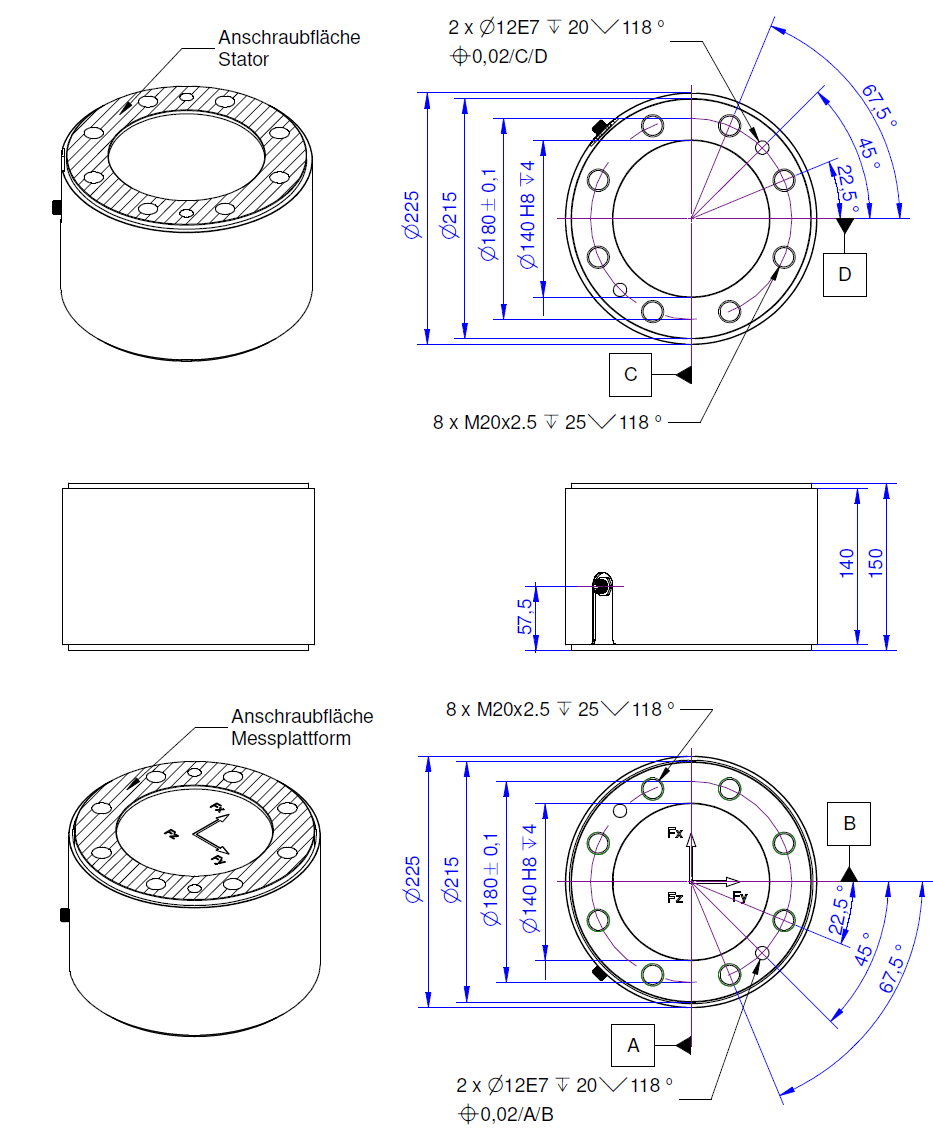

3-axis force transducer from ± 100 kN to ± 400kN - Ø225 mm x 150 mm

- Measuring ranges: Fx:yz 100 kN / 100 kN / 200 kN or 200 kN / 200 kN / 400 kN

- Tensile and compression force

- Construction: Stainless steel

- Non-linearity: 0.2 % PE

- Operating temperature: -10°C to 85°C

- Transmission of force: 8 x M20x2.5 threads

- Dimension: 225 mm x 150 mm

- Output: Integrated connector

Introduction

The K3A225 sensor is designed to measure forces in the three components Fx, Fy, Fz. With a cylindrical profile and reduced dimensions, this 3-axis sensor is easily installed on machine tools, robot arms, and test benches. The mounting is done by 8 M16x2 threads and centering pins. Output connector MP11 24 pins. The measurement ranges are :

- Option 1: 100kN in x and y, and 200kN in z.

- Option 2: 200 kN in x and y, and 400 kN in z

Packaging, Acquisition

The accuracy is about 0.2% of the measurement range, thanks to the temperature compensation of the calibration over the range -10 to 70°C, and the compensation of crosstalks. The overload capacity is 150% (i.e. a maximum allowable overload of 50% of the measuring range). The torque limit is 40000 Nm, and the maximum allowable bending moment is 10000 Nm.

Each transducer is delivered with a factory calibration certificate. Calibration to specific measuring ranges is possible (optional), as well as ISO-17025 calibration.

The acquisition of the raw measurement signals is done with :

- a PC or PLC acquisition system equipped with a strain gage bridge input card

- or via a conditioning module for strain gage bridge with analog or digital output, then a PC or a standard acquisition system.

PM Instrumentation recommends the GSV series of digital interface conditioning modules for their ease of use and accuracy:

- the GSV-4USB (Conditioner / acquisition module, 4 analog inputs) or its Bluetooth version GSV-4BT M12, which can be equipped with an optional data logger

- the GSV-8DS (High performance module, 8 analog inputs)

- the GSV-6LTE, equipped with a data logger and wireless connectivity

The GSV-1A4 conditioner is equivalent to the GSV-4USB, with 4 analog outputs instead of one serial output.

A visualization and acquisition software is included with these modules (GSV-multi). Dll and VI files are also provided for the development of an application under Labview or in C / Visual Studio / C++ / .net

Applications

The K3A225 is recommended for:

- Robotics testing

- Machine tool instrumentation

- Monitoring of production machines

- Medical equipment

- Test benches

- Type

- beam sensor

- Number of Axis

- 3 Axis

- Precision (max error)

- 0.5 %

- Nonlinearity (% FS)

- ± 0.2 %

- Operating temperature range

- -10 à 85 °C

- Zero Balance

- 0.01 %PE/°C

- Sensibilité du gain

- 0.01 %/°C

- Tension d'alimentation

- 10 Vcc

- Measurement direction

- Traction & Compress.

- Surcharge

- 150 %PE

- Housing

- Steel

- Measuring Range (Force)

- 100 - 250 kN, > 250 kN

- Transducer Series

- K3A

- Application

- High Accuracy

- Calibration option (with provision of a calibration certificate)

- Cabling service - custom cable (protection and cable length)

- Measurement range

- Conditioners (GSV 8DC SubD44 recommended)

- Cables and connectors (MP11/24p/f-SubD44/m recommended)

Produits associés

GSV-8DS

GSV-4USB

K3A125 - 3 axes - 30 à 120 kN - Ø125