Thread checking

- Automated tap control: presence / absence / partial completion

- Detection quality < 4 PPM

- Detection time < 0.1 s

- Use on aluminium, steel, cast iron, copper...

- 4 tapping detection probes (M5 to M14)

- Push button teach-in

- IP67 sensor, insensitive to oil, cutting fluid/dust etc...

- Tapping control by backflow

- Tapping control by deformation

- Suitable for robotic tapping stations

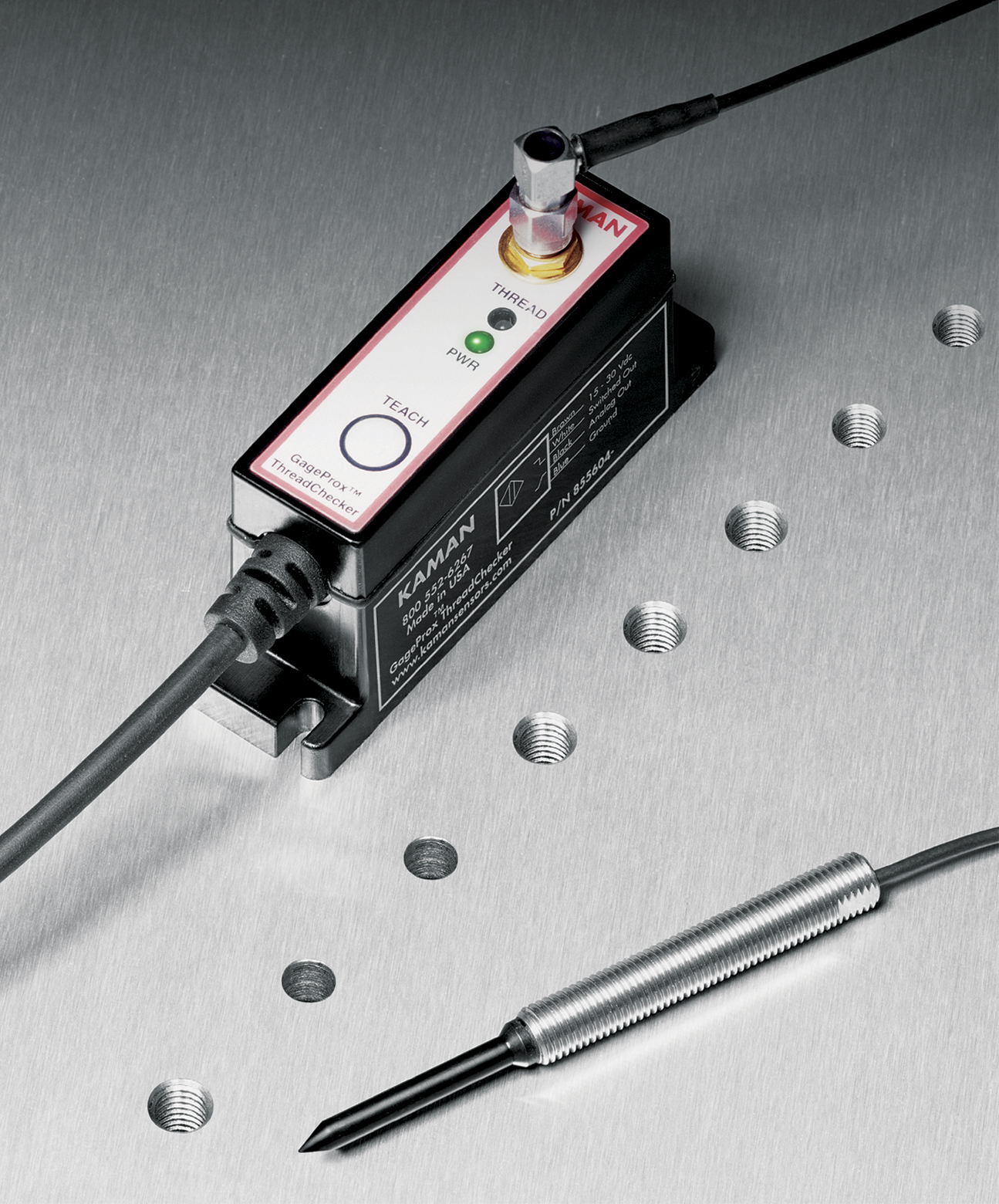

Automated thread checking system

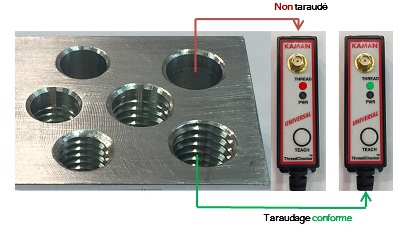

The ThreadChecker is a unique solution for automated compliance monitoring of the presence or absence of a thread in production. The ThreadChecker detects:

- The presence of a thread (tapped hole)

- The absence of a thread (smooth hole)

- Partial tapping on the height/depth

- Checking in 0.1 seconds / cm depth

The inspection is performed on finished parts during or at the end of production, directly at the tapping station. The Threadchecker is compatible with a wide range of materials (aluminium, copper, steel or cast iron) and the defect detection level is below 4 PPM.

Functional principle

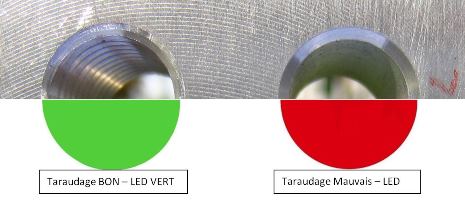

The ThreadChecker system uses eddy current technology: a coil positioned at the end of the probe resonates in the vicinity of the metals. The resulting impedance change is measured by the electronics and produces an electrical signal in the form of a DC voltage and a binary output (good/not good). The electrical signal from the probe is proportional to the volume of material in the vicinity. The system differentiates between a smooth hole and a tapped hole.

Advantages

- The probe is IP67 waterproof: it can be used in cutting fluid, oil or harsh conditions

- The control is insensitive to the brightness of the workpiece and can be performed during machining

- Sensor electronics provide TTL output and LED indication (good or bad)

- Fast and reliable tap inspection

- Suitable for inspection of threaded holes by upsetting

Type of products that can be controlled

- The parts to be checked can be machined, stamped parts

- Machined castings (not on raw tapped parts)

- Non-contact inspection of threaded inserts and HELICOILs

- Aluminium, copper, steel, cast iron or any other metal part.

- Eddy current tapping control (non-contact)

- Can be used in conjunction with machine vision

Installation

The system consists of universal electronics and a detection probe (4 references, from M5 to M12). The electronics are compatible with all types of probe. The probe is easily integrated into the tool holder or the arm of a robot thanks to the M8 to M12 thread. The electronics can be mounted on a Din Rail or by screw.

The electronics are powered by 24 VDC and deliver a digital signal.

| Threading | Reference | Thread | B | C |

|---|---|---|---|---|

| M6 - M7 | 855641-602 | M8x1 | 4.0 | 25 |

| M8 - M9 | 855641-802 | M8x1 | 5.8 | 25 |

| M10 - M11 | 855641-1002 | M12x1 | 7.6 | 25 |

| M12 - M12 | 855641-1202 | M12x1 | 9.5 | 25 |

Learning and commissioning

The commissioning of the Threadchecker starts with a learning process. The electronics are configured in learning mode and then a first detection is carried out on conforming and then non-conforming holes. After this training, the system is operational. The training must be carried out on parts that are representative of the parts to be inspected. The training is permanent for given parts. In the case of upsetting taps, the training procedure is adapted to the different configurations.

✓ The system is ready for use

✓ The system is ready for use

Dimensions and connection

Electrical connections (0-10VDC output is used for internal controls)

- M5 à M12

- Type

- Thread

- Tension d'alimentation

- 24 Vcc

- Protection Class

- IP67

- Control on threads from M6 to M12

- 24 VDC power supply

- Probe control tools

Please consult us

Produits associés

KD-2446

KD-2306 | OEM-2306

SC-2440