Customer

- Industrial with assembly line

Need / Problem

Following an increase in defects on an assembly line, the customer's quality department realised that their origin was the application of excessive torque to screws and bolts during assembly. The customer asked us to remedy the situation.

Solution

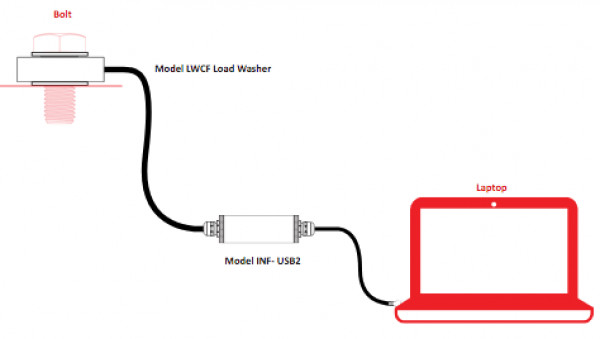

Clamping station instrumentation consisting of:

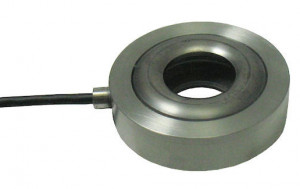

- A load cell LWCF type load washer, measuring the compression force applied during clamping.

- A data acquisition module GSV-6K records the forces, and displays the maximum and final values for each operation.

Results / Customer benefits

- The process is now under control, with near zero defect quality.

- Tightening values are saved for traceability purposes and process optimisation.