Non-contact displacement: Overview

Non-contact eddy current displacement sensors are used to measure distances, displacements or positions. They measure the distance between the sensor face and metal objects which can be magnetic or non-magnetic (stainless steel, aluminium, copper, steel).

The vibration measurement can be performed on a fixed part or on a rotating axis. The very high bandwidth of these eddy current sensors allows the measurement of very low amplitude and high frequency vibrations (50 kHz).

Displacement measurements are from a few microphones to several millimetres from the sensor face. KAMAN displacement transducers can operate at temperatures from 70 Kelvin to 538 °C.

KAMAN eddy current sensors are used in many applications in research and production. They are used, among other things, to measure the thickness or position of metal parts, vibrations, axis centering, out-of-roundness, bearing wear or displacement of vibrating parts, thus giving the amplitude and frequency of the latter.

Non-contact displacement measurement: The technologies

Eddy current displacement measurement systems are characterised by a number of parameters related to the technology:

Type of measuring environment:

- Sensors for working temperatures up to 200°C.

- Sensors for measurements from 20 to 800 Kelvin (-250 to 550°C)

- Sensors exposed to high pressure

- Sensors exposed to radiation

- Sensors in extreme vibration environments

Type of sensor construction:

- Epoxy sensors for ambient temperature measurements up to 100°C under atmospheric humidity conditions.

- PEEK sensors for measurements between Cryo and 200°C. These sensors can withstand low pressure fluid splashes.

- Stainless steel sensors: for extreme temperatures with maximum pressures of 250 bar and temperatures < 538°C.

**Choice of conditioning electronics

-

Digital with easy calibration and temperature compensation. The electronics are compatible with all single coil sensors.

-

Analogue with high bandwidth and flexibility of configuration according to target, cable and measurement environment.

-

EOM for industrial OEM applications

Displacement measurement : Our displacement sensor products

-

Inductive displacement sensors for extreme conditions View products

-

LVDT Displacement Transducers View products

-

Rugged Industrial LVDT Displacement Transducers View Products

-

Cable or taut wire displacement transducers View products

Applications

This sensor technology is suitable for all industries in the automotive, aerospace, mechanical, production or railway sectors:

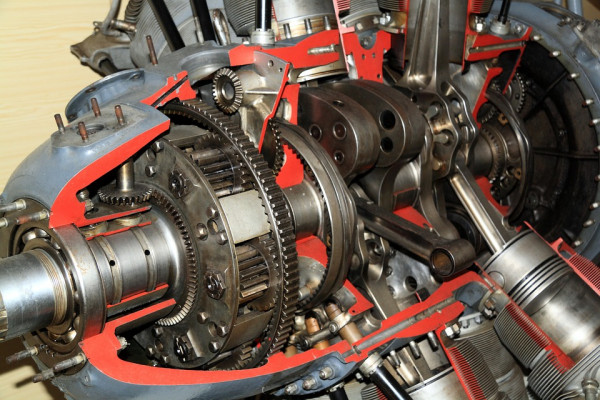

- Measurement of position and vibration of rotating parts

- Position and vibration measurement of rotating parts

- Air and magnetic bearings

- Axis centring, vibration measurement

- Measurement of cutting tools, hot deformation measurement

- Surface inspection after polishing

- Valve and valve position

- Expansion measurement under load and temperature

- Sample thickness measurement, continuous sheet thickness measurement

- Positioning under high pressure and temperature