Criteria for selecting a load cell or sensor

The first criteria in choosing a transducer are related to the type of test to be performed, the metrological requirements and the duration of the tests.

The type of test to be performed will determine the form of the transducer to be chosen, for example :

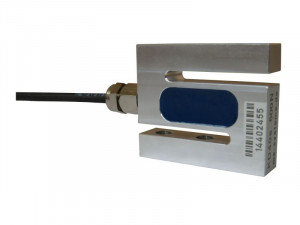

- For a sample breaking machine, occasionally used for compliance testing, an S-shaped load cell can be selected. They have very good accuracy and repeatability, low cost and are often available from stock. Examples

- For a fatigue test bench** where samples will be loaded to failure, a load cell that combines durability, accuracy and stability should be selected. This type of test generally requires high load cells Examples

- Finally, for force measurements in multiple directions or if the direction of the force is uncontrolled, a multi-axis load cell is recommended. Other important parameters are: temperature sensitivity, metrological data, measurement accuracy, shape of the load cell, price and availability, direction of force Examples

(For information 10 N = 1.01971621 kg, 10kN = 1019.7 kg and 100 MN = 10197 Tons)

Industrial force measurement: our force products

- S force sensors View products

- Wafer sensors : View products

- Beam & Washer Sensors**: View Products

- 6 axis force sensors** : View products

- Button force sensors : View products

Force measurement: Applications

Examples of applications :

- Static and dynamic testing, Material control

- Strength of materials testing, Hexapod testing

- Practical work in technical training, engineering school and university laboratory

- Model and sample testing, Static and dynamic force in wind tunnels

- Stress measurement in medical technology / prosthetics / orthopaedic technology

- Collision detection, measurements in sports medicine