Customer

Designers and users of industrial robots

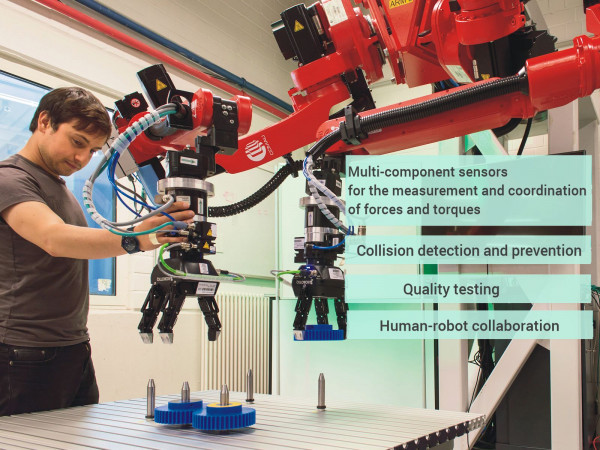

Problem

To improve the precision of the grip in effort and position.

Solution

The use of 6-axis force transducers such as the K6D80 improves the performance, reliability and flexibility of industrial robots by providing a dual position and force control loop.

| The force/torque sensor (4) is mounted between the robot (1) via flange (2) and mounting plate (3), and to the articulated gripper (7) via measuring plate (5) and flange (6). |

|---|

The high accuracy of the K6D80 sensor is achieved by the very rigid design, and an optimised calibration process.

Results and customer benefits

- Significant improvement in gripping sensitivity and accuracy

- Reduction of non-conformities and cycle times

- Early detection of defects by force feedback

- Drift measurement