Displacement measurement : General overview

Displacement measurement is carried out using a displacement sensor with or without contact with the moving part. PM Instrumentation is able to provide displacement measurement solutions meeting the most severe constraints and expectations, for the instrumentation of a test, a test bench or an embedded use:

- measurement range (from a few nanometres to a few tens of mm)

- resolution (from 0.1 nm to mm)

- bandwidth (from 1 Hz to 100 kHz)

- space requirement, integration envisaged

- environmental conditions (cryogenics at 600°C, vacuum at 350 bars, immersible sensors, use in radioactive environments, etc.)

Displacement measurement applications

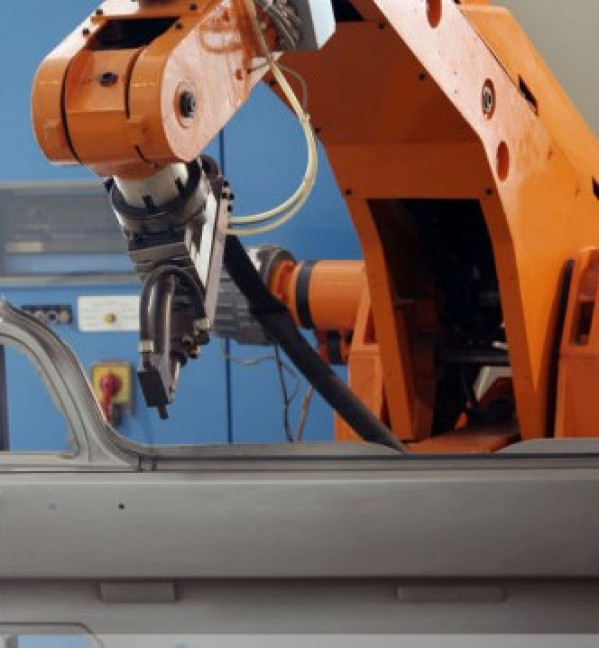

Industrial sectors include aerospace, manufacturing, automotive, railway, civil engineering

- Monitoring the position of a valve

- Measuring the thickness of an impregnation

- Measurement of out-of-roundness on a rotating shaft

- Vibration measurement of rotating parts.

- Shaft centring / shaft alignment

- Measurement of expansion

- Measurement of suspension travel

- Surface inspection after polishing

- Continuous sheet thickness measurement

- Positioning under high pressure and temperature

- Rotational speed measurement

- Underwater displacement measurement

- Cylinder instrumentation

- Crack measurement

- Crack measurement

- etc...

Displacement measurement : Technologies offered

Taut wire or potentiometric sensors : The cable is directly or indirectly linked to the displacement to be measured and the potentiometer, the output signal is linear and continuous, it is a simple and economical sensor for a complex and accurate measurement. See products

Eddy current sensors: They measure the distance between the face of the sensor and metal objects which may be magnetic or non-magnetic (stainless steel, aluminium, copper). The displacement measurement is done without contact with the part to be measured. See products

LVDT sensor: The principle of the LVDT is to measure the position of the core inside the sensor body. The output signal is proportional to the position of the core. It can be moved either by a probe system or by connecting it with a threaded rod (free core). See products

Inductive sensor : Inductive sensors are characterised by their robustness, accuracy, high frequency response (10kHz) and ease of use. Power supply 5Vdc (and optional 13 to 28Vdc). See products